What Are Raschig Rings Used For?

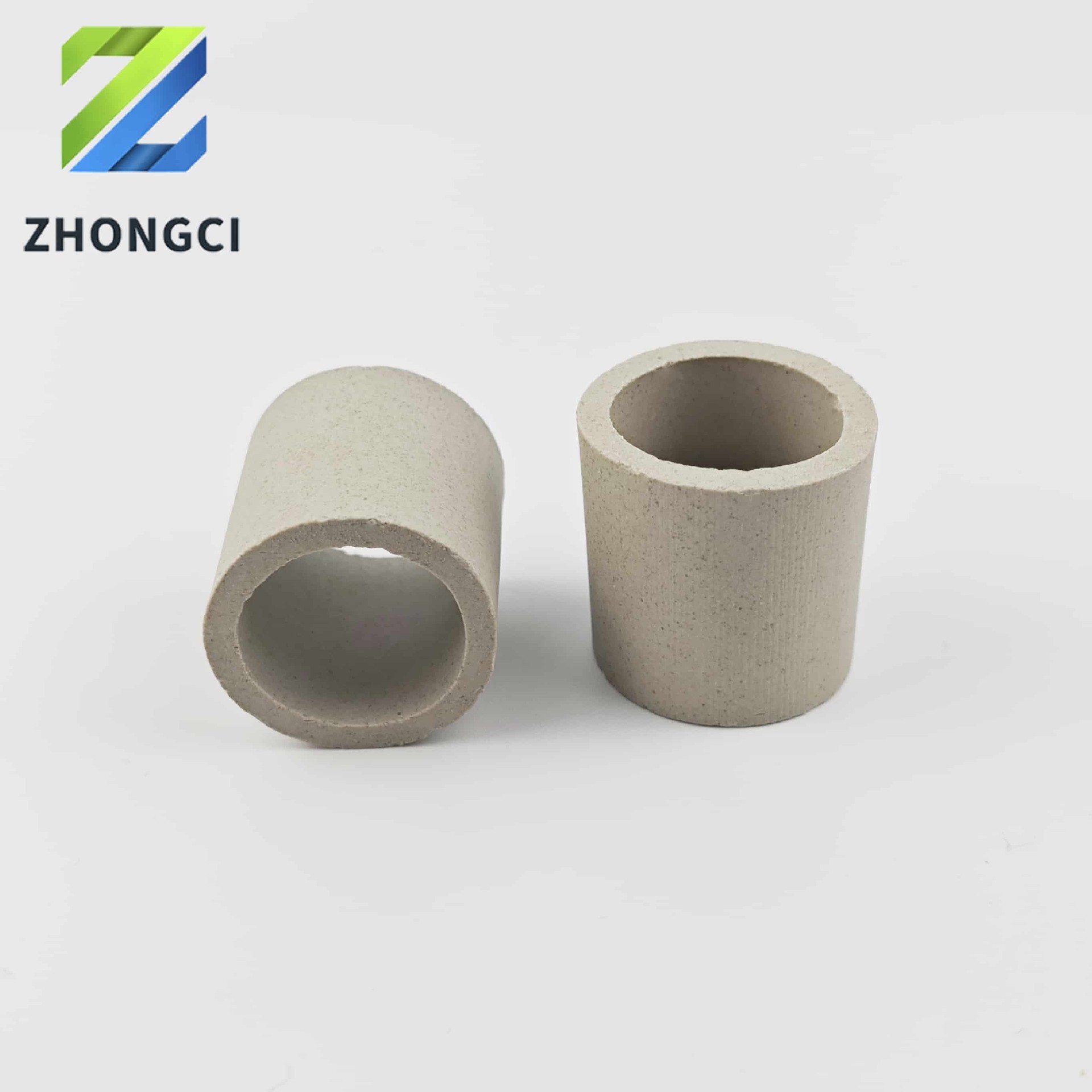

Raschig Rings are a type of random packing material used in various industrial applications due to their high chemical resistance, excellent thermal stability, and efficient mass transfer properties. They are available in different materials such as ceramic, metal, and plastic, making them suitable for a wide range of processes. Below are the primary uses of Raschig Rings:

1. Distillation Columns

Used as packing material to increase surface area and enhance the separation of liquid mixtures in distillation processes.

Commonly applied in chemical, petrochemical, and pharmaceutical industries.

2. Absorption and Stripping Towers

Raschig Rings facilitate gas-liquid contact, improving the efficiency of gas absorption and solvent recovery.

Applied in scrubbers and air purification systems to remove pollutants like sulfur dioxide (SO₂) and ammonia (NH₃).

3. Chemical Processing Equipment

Used in reactors and gas-liquid contactors to support catalytic reactions.

Helps in chemical absorption, degassing, and purification processes.

4. Waste Gas and Water Treatment

Found in gas scrubbers for neutralizing harmful emissions from industrial exhaust streams.

Used in wastewater treatment plants for biological filtration and chemical treatment.

5. Petrochemical and Refinery Applications

Used in fractionation towers for crude oil distillation and hydrocarbon separation.

Helps improve mass transfer efficiency in oil refining and chemical production.

6. Nuclear Industry

Ceramic Raschig Rings are used as neutron absorbers in nuclear reactors to control and moderate fission reactions.

7. Heat Exchange Systems

Applied in cooling towers and heat transfer equipment to enhance thermal efficiency.

Conclusion

Raschig Rings play a critical role in industrial processes that require efficient gas-liquid contact, separation, and purification. Their high durability and versatility make them essential for distillation, absorption, wastewater treatment, petrochemicals, and even nuclear applications.

2025-03-25

2025-03-25

0799-6335986

0799-6335986

+86-18107991684

+86-18107991684

yuna@chempacking.cn

yuna@chempacking.cn

Hmoe

Hmoe