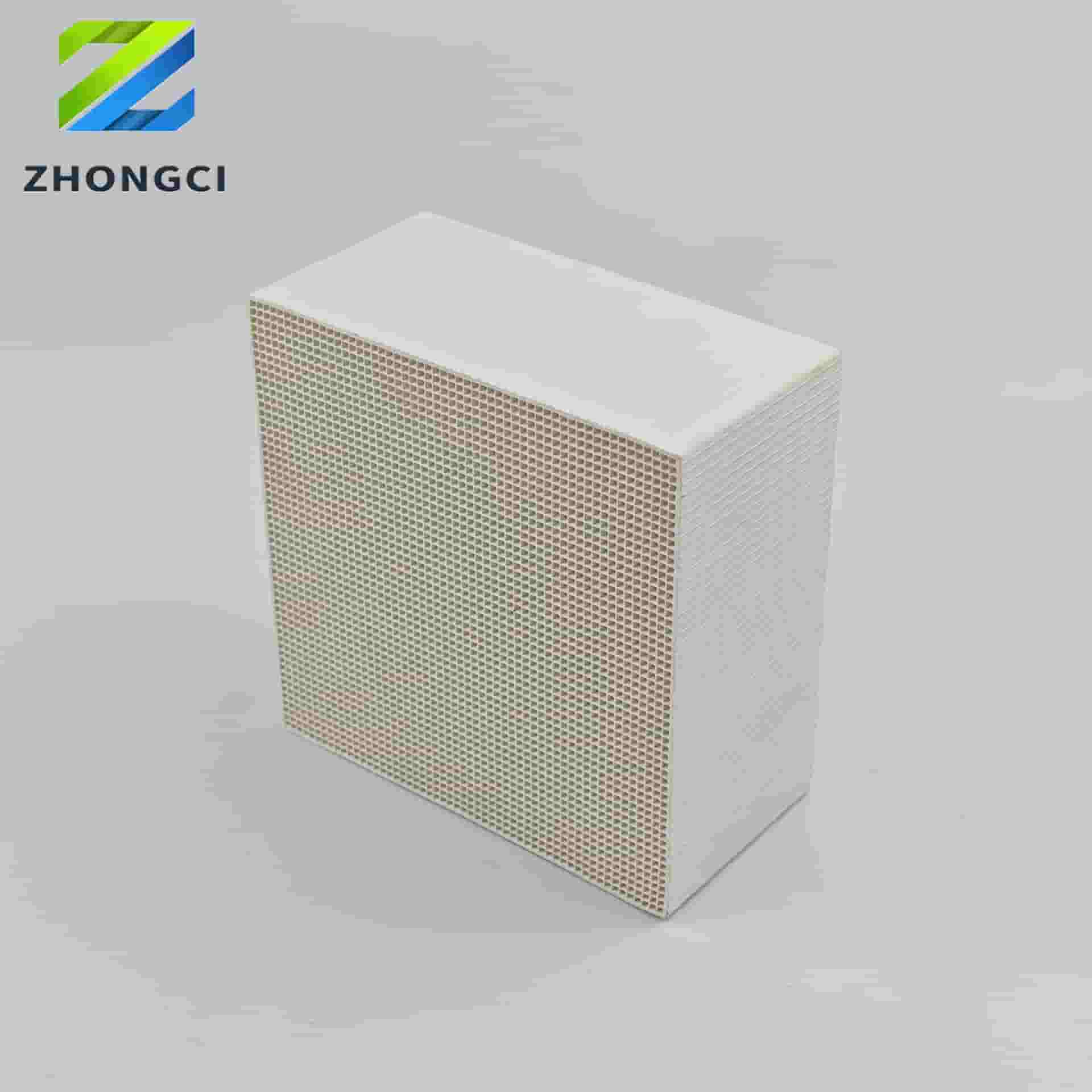

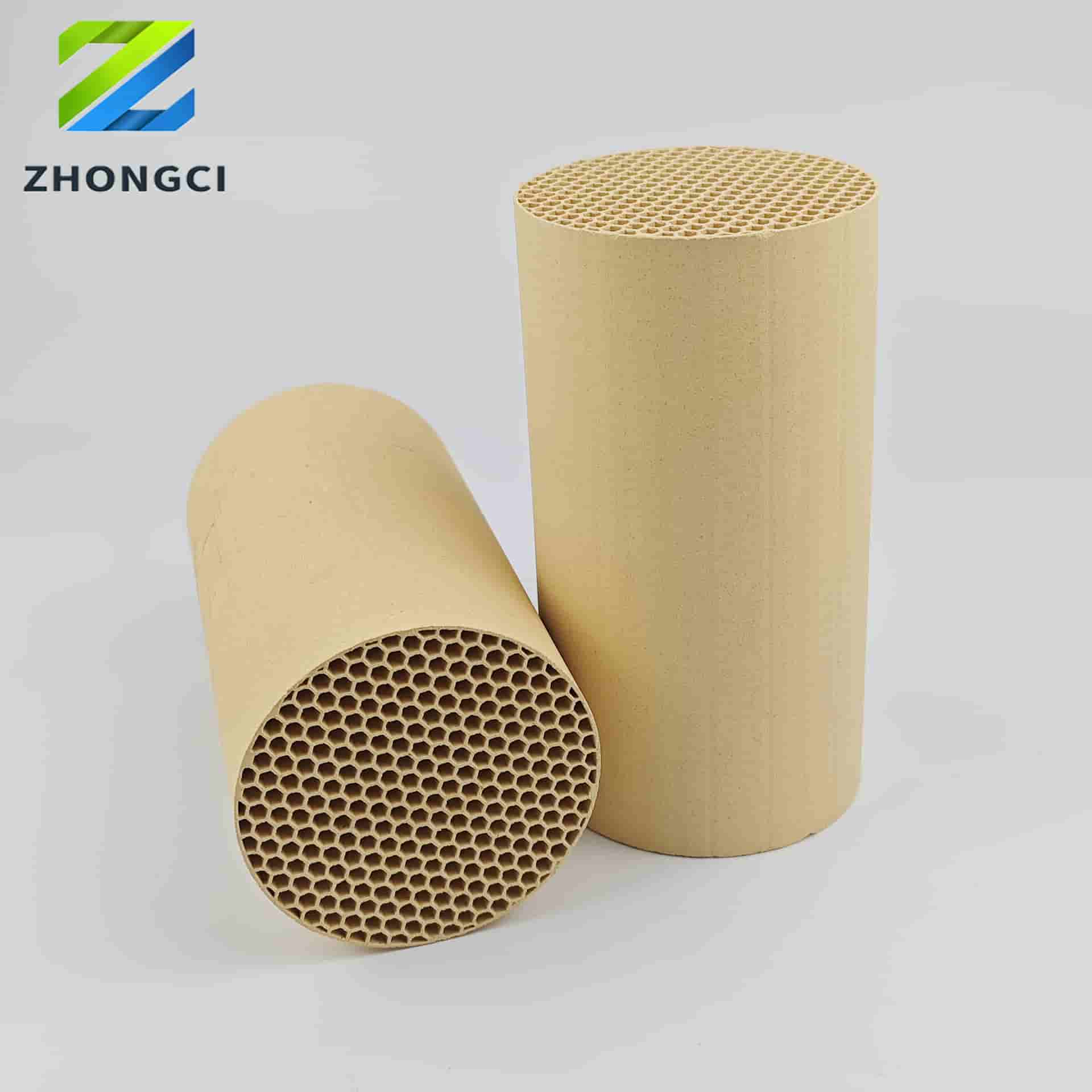

What is honeycomb ceramic

Honeycomb ceramics can be made from a variety of materials. The main materials are: cordierite, mullite, aluminum titanate, activated carbon, silicon carbide, activated alumina, zirconia, silicon nitride and cordierite-mullite, cordierite-aluminum titanate composite matrix.

Honeycomb ceramics can be divided into four categories according to the use of heat storage, filler, catalyst carrier and filter material.

The heat capacity of honeycomb ceramic accumulator is more than 1000kJ/kg, the maximum use temperature of the product is more than 1700℃, and the fuel can be saved by more than 40% in the furnace, roaster, soaking furnace, cracking furnace and other kilns, the output can be increased by more than 15%, and the emission flue gas temperature is less than 150℃.

Honeycomb ceramic packing than other shape packing surface area is larger, better strength and other advantages, can make the vapor liquid distribution more uniform, bed resistance is reduced, the effect is better, and can extend the service life, in the petrochemical, pharmaceutical and fine chemical industry as a filler effect is quite good.

Honeycomb ceramics have more advantages in terms of catalysts. The honeycomb ceramic material is used as the carrier, the unique coating material is made of precious metals, rare earth metals and transition metals, so it has the advantages of high catalytic activity, good thermal stability, long service life, high strength and so on.

Honeycomb ceramic as a filter material has the following advantages: good chemical stability, acid and alkali resistance and organic solvent; Excellent resistance to hot and cold, the working temperature can be up to 1000℃; Good antibacterial performance, not easy to be degraded by bacteria, not easy to plug and easy to regenerate; Strong structural stability, narrow pore size distribution, high permeability; Non-toxic, especially for food and drug handling. It is mainly used in the metallurgical industry. The specific surface area of honeycomb ceramic body is large, which improves the ability of the filter to absorb and capture fine impurities, and the filtration effect is better than that of traditional porous ceramics, and the metal liquid flow is stable.

2025-03-25

2025-03-25

0799-6335986

0799-6335986

+86-18107991684

+86-18107991684

yuna@chempacking.cn

yuna@chempacking.cn

Hmoe

Hmoe