Metal structured packings are highly efficient and versatile components used in separation equipment, with extensive applications across various industrial fields. Below is a summary of their specific applications and characteristics in different sectors:

1. Chemical Industry

Applications: Distillation, absorption, extraction, and other separation processes.

Characteristics: High mass transfer efficiency, low pressure drop, suitable for complex chemical separation processes.

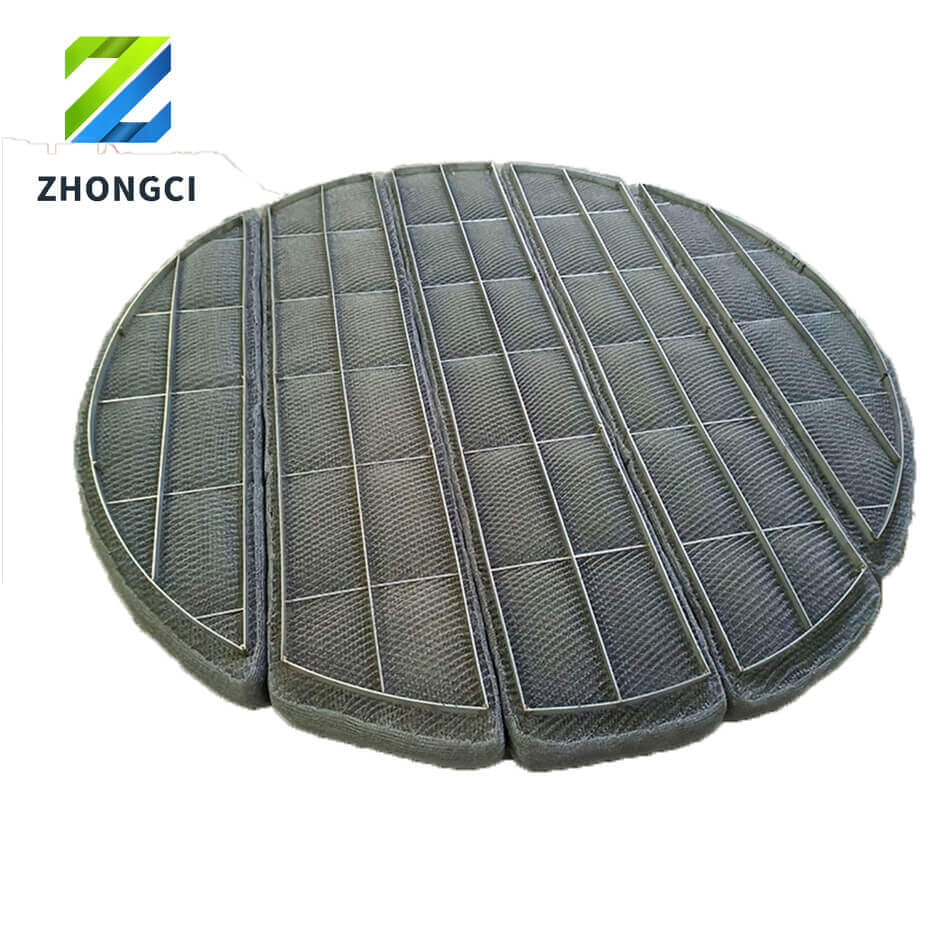

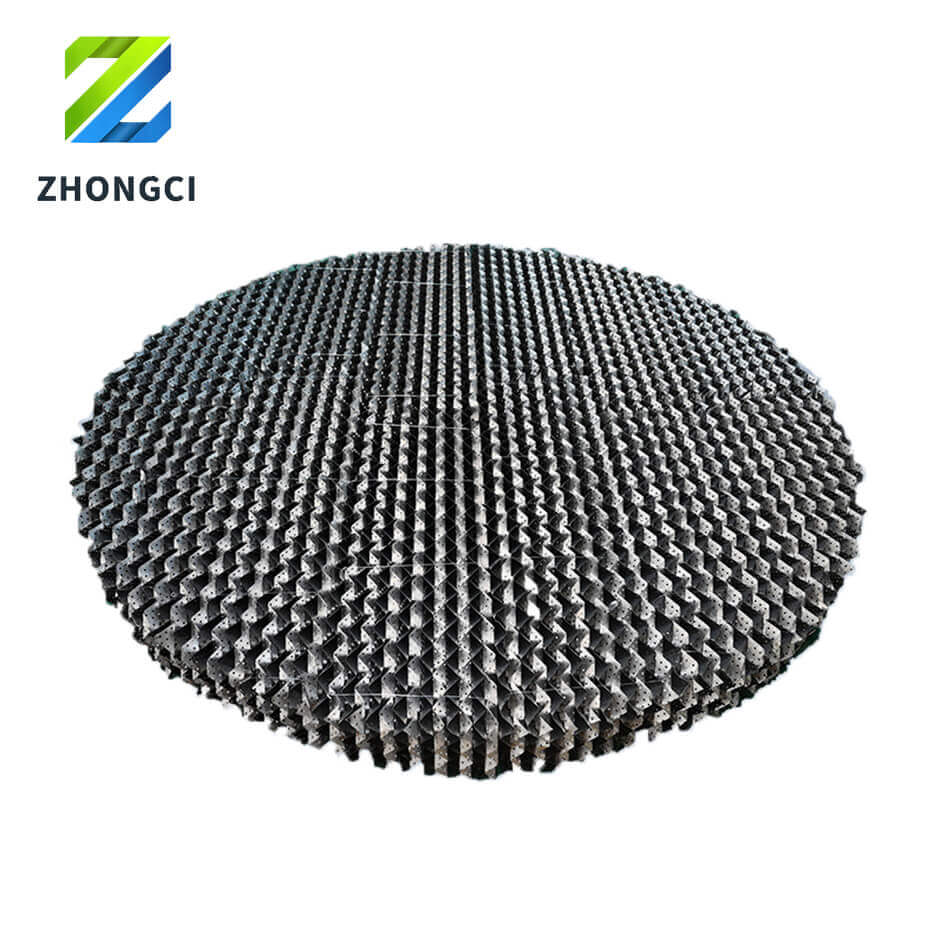

Common Types: Hole-type corrugated packing, plate-type corrugated packing, perforated corrugated packing, etc.

2. Petrochemical Industry

Applications: Crude oil refining, natural gas processing, hydrocarbon separation, etc.

Characteristics: High temperature and corrosion resistance, suitable for demanding petrochemical processes.

Common Types: Wire mesh corrugated packing, ring-type corrugated packing.

3. Environmental Protection

Applications: Waste gas treatment (e.g., desulfurization, denitrification), wastewater treatment (e.g., organic matter removal).

Characteristics: Efficient mass transfer, effective pollutant removal, and improved treatment efficiency in environmental equipment.

Common Types: Hole-type corrugated packing, plate-type corrugated packing.

4. Food Industry

Applications: Alcohol distillation, flavor extraction, food-grade solvent separation, etc.

Characteristics: Easy to clean, meets hygiene standards, ensures safety and quality in food production.

Common Types: Wire mesh corrugated packing, ring-type corrugated packing.

5. Pharmaceutical Industry

Applications: Separation and purification of pharmaceutical components.

Characteristics: High-precision separation, meeting strict purity requirements in the pharmaceutical industry.

Common Types: Wire mesh corrugated packing, perforated corrugated packing.

6. Nuclear Industry

Applications: Isotope separation, nuclear waste treatment.

Characteristics: Radiation and corrosion resistance, suitable for extreme environments.

Common Types: Hole-type corrugated packing, plate-type corrugated packing.

7. Other Fields

Applications: Air separation (e.g., oxygen and nitrogen production), refrigerant recovery, etc.

Characteristics: High efficiency and energy savings, suitable for various industrial gas treatments.

Characteristics of Metal Structured Packings

High Mass Transfer Efficiency: Provides a larger specific surface area, enhancing mass transfer.

Low Pressure Drop: Reduces energy consumption and improves equipment efficiency.

Easy to Clean and Replace: Lowers maintenance costs and extends equipment lifespan.

Diverse Specifications: Common sizes include 500mm×500mm, 1000mm×1000mm, and custom options are available.

Future Prospects

With continuous advancements in industrial technology, the application fields of metal structured packings will further expand, particularly in green chemistry, clean energy, and environmental protection technologies. Their high efficiency and energy-saving features will play an increasingly significant role.

2025-04-22

2025-04-22

0799-6335986

0799-6335986

+86-18107991684

+86-18107991684

yuna@chempacking.cn

yuna@chempacking.cn

Hmoe

Hmoe