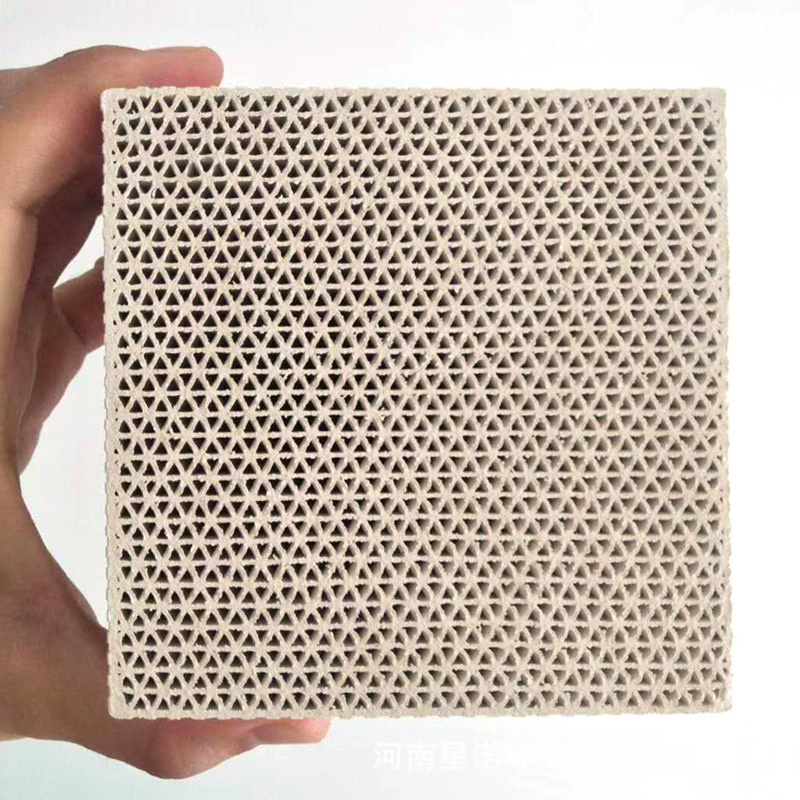

Honeycomb Zeolite Molecular Sieve for VOC Adsorption & Concentration

This product is engineered for efficient adsorption and enrichment of diverse volatile organic compounds (VOCs). Based on manufacturing processes, it is classified into two types:

Extrusion-molded (monolithic zeolite structures)

Wash-coated (zeolite layers deposited on ceramic/polymer substrates)

Key Advantages

| Technical Superiority | Application Impact | |

1. Uniform Crystallinity | Precisely controlled pore geometry (e.g., 0.4–1.2 nm micropores) with <5% size deviation | Ensures consistent VOC capture kinetics and predictable breakthrough curves |

2. Optimized Porosity | BET surface area: 400–700 m²/g; Dynamic adsorption capacity: 8–15 wt% for toluene @25°C | Outperforms activated carbon by 20–30% in high-humidity (RH>60%) environments |

3. Thermal Resilience | Stable up to 650°C (short-term), hydrothermal stability at 300°C/steam for 500+ hours | Enables >5,000 regeneration cycles via 180–220°C desorption without structural collapse |

4. Eco-Safety | Zero heavy metals, non-flammable (vs. activated carbon), RoHS/REACH compliant | Eliminates hazardous waste disposal costs and fire risks |

5. Molecular Selectivity | Separation factors up to 15:1 for xylene/water vapor (Si/Al ratio >200) | Targeted removal of non-polar VOCs (e.g., benzene, hexane) in humid gas streams |

6. Acid Resistance | <3% capacity loss after 500h exposure to 10% H₂SO₄ vapor or pH2–pH12 liquid | Ideal for acid gas-containing exhaust (e.g., semiconductor etching, waste incineration) |

Process-Specific Features

Extrusion-Molded Type

Mechanical Strength: Axial crush resistance >1.2 MPa (100 CPSI density)

Geometry Flexibility: Custom channel shapes (square/hexagonal) with 60–65% open porosity

Wash-Coated Type

Low Pressure Drop: ΔP <300 Pa/m at 1 m/s face velocity (200 μm coating thickness)

Substrate Options: Cordierite (650°C limit) or metal alloys (900°C capable)

Performance Validation Data

VOC Removal Efficiency: >95% for C6–C10 hydrocarbons at 10,000 h⁻¹ space velocity

Lifespan: 5–8 years with biweekly thermal regeneration (200°C/N₂ purge)

Chemical Compatibility: Resists SO₂ (200 ppm), HCl (100 ppm), and Cl₂ (50 ppm)

For applications requiring acid gas co-adsorption (e.g., SO₂+VOCs) or high-temperature catalysis, specify your gas composition for tailored material recommendations.

2025-04-02

2025-04-02

0799-6335986

0799-6335986

+86-18107991684

+86-18107991684

yuna@chempacking.cn

yuna@chempacking.cn

Hmoe

Hmoe