Silicon Nitride Ceramic Balls: Key Properties and Applications

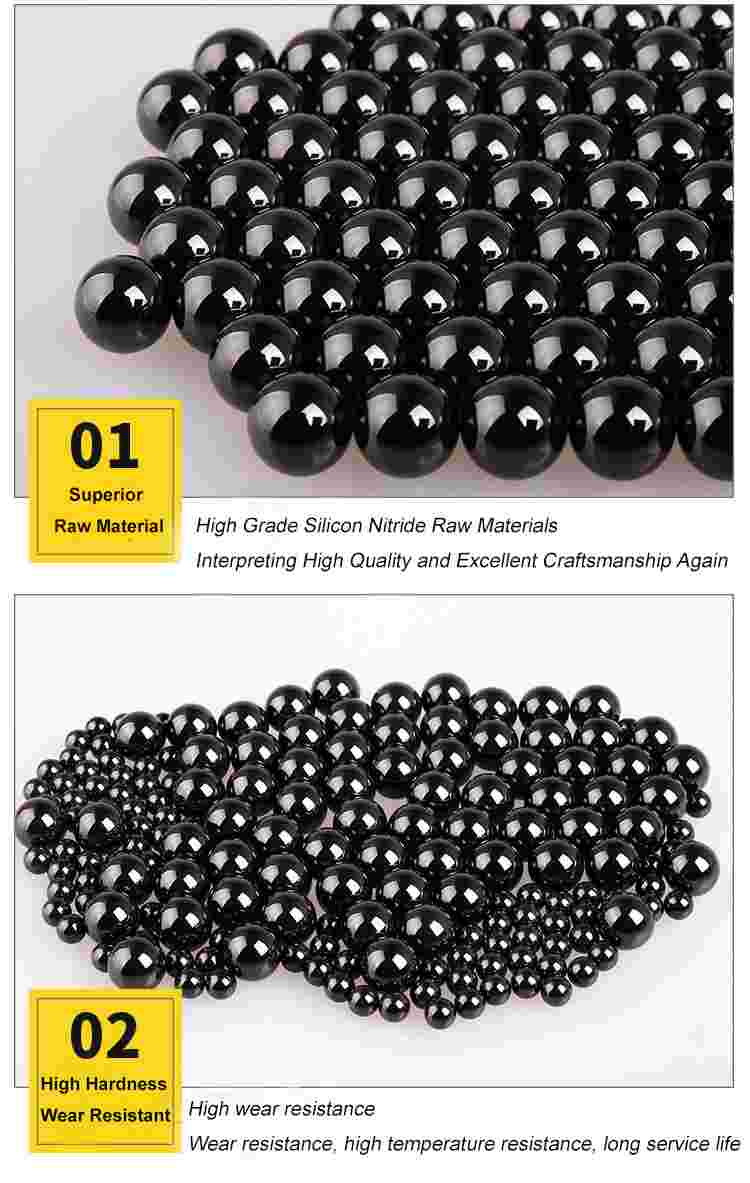

Core Properties

Low Thermal Expansion Coefficient

Only 3.2×10⁻⁶/K (1/4 that of bearing steel), ensuring excellent dimensional stability in high-temperature or precision applications.

Self-Lubricating

Reduces dependency on external lubricants, minimizing contamination risks—ideal for clean environments (e.g., food processing, vacuum systems).

Chemical Resistance

Withstands harsh acids, alkalis, and solvents, making it suitable for chemical pumps, valves, and reactors.

High Mechanical Strength & Fracture Toughness

Superior hardness and wear resistance for heavy-load or high-impact conditions (e.g., bearings, cutting tools).

Low Thermal Conductivity

Provides thermal insulation in heat exchangers or high-temperature equipment.

Key Applications

Bearings: High-speed spindle bearings (machine tools, aerospace), corrosion-resistant marine bearings, or oil-free systems.

Seals & Valves: Mechanical seals for chemical pumps, ensuring leak-free performance in aggressive media.

Automotive: Turbocharger bearings, engine components (lightweight & heat-resistant).

Energy/Chemical: Heat exchanger parts, reactor linings, and nozzles for durability in corrosive environments.

Specialized Uses: Semiconductor manufacturing, vacuum chambers, and medical devices where cleanliness is critical.

Advantages Over Metals

Silicon nitride ceramics overcome limitations of steel—such as corrosion, lubrication needs, and thermal deformation—enabling reliable performance in extreme conditions.

2025-04-23

2025-04-23 0799-6335986

0799-6335986

+86-18107991684

+86-18107991684

yuna@chempacking.cn

yuna@chempacking.cn

Hmoe

Hmoe