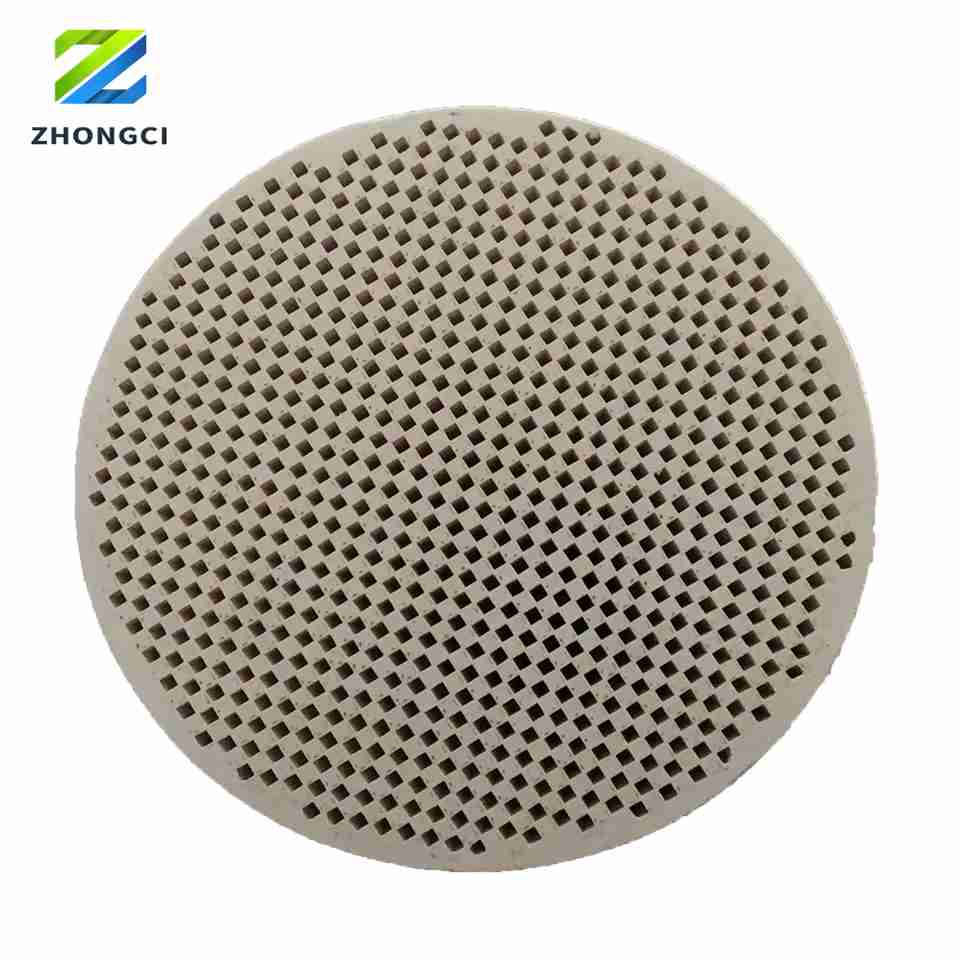

catalytic converter for diesel generator euro 4 euro 5 universal ceramic honeycomb for catalyst converters

Honeycomb Ceramic DPF Filter Diesel Particulate Filter DPF DOC

DPF filter are one kind of wall-flow monolith, the channels are open at one side, but plugged at the other. it will be installed in the diesel car exhaust system, to reduce particulate matters (PM) of exhaust by trapped. The main components of Diesel engine exhaust are particulate matter(PM), carbon monoxide(CO) and hydrocarbons(HC), Diesel Particulate Filters Can reduce them by 90+% from diesel engines

Quick Details

OE NO.: 53010158

Size: Depend on client

Warranty: 5years

Place of Origin: China

Brand Name: Zhongci

Car Model: All

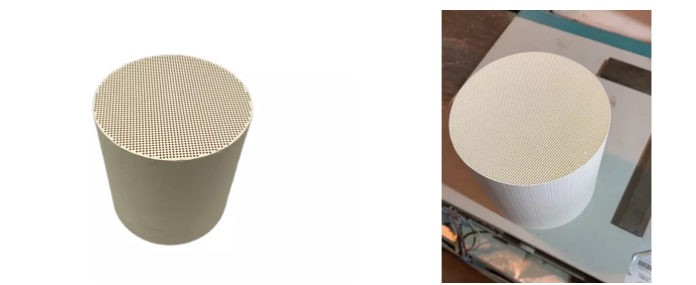

Model Number: 118*152.4mm 144*152.4mm

Product Name: dpf honeycomb ceramic

Channels: Round

CPSI: 100/200cpsi

Shape: Cylinder

Usage: DPF

Certification: TS

Structure:

The DPF is a honeycomb ceramic monolith with alternating channels plugged at opposite ends.

This design forces the exhaust gas to flow through the porous walls of the ceramic channels, trapping particulate matter while allowing gases to pass through.

Filtration Process:

As exhaust gases flow through the DPF, particulate matter (PM), such as soot and ash, is trapped in the porous walls of the ceramic.

The clean gas exits the filter, significantly reducing emissions.

Regeneration:

Passive Regeneration: Occurs naturally when the exhaust temperature is high enough to burn off the trapped soot.

Active Regeneration: The engine management system increases the exhaust temperature (e.g., by injecting extra fuel) to burn off the accumulated soot.

Over time, the trapped particulate matter accumulates and can clog the filter.

To prevent this, the DPF undergoes regeneration:

Material:

Made from high-quality ceramic materials such as silicon carbide (SiC) or cordierite, which are durable and can withstand high temperatures and thermal shocks.

High Filtration Efficiency:

Capable of reducing particulate matter (PM) emissions by 90% or more.

Low Pressure Drop:

The honeycomb structure ensures efficient gas flow with minimal resistance, maintaining engine performance.

Durability:

Resistant to high temperatures, chemical corrosion, and mechanical stress.

Compatibility:

Often used in conjunction with Diesel Oxidation Catalysts (DOCs) to further reduce CO and HC emissions.

Automotive: Installed in diesel cars, trucks, and buses to meet emission regulations (e.g., Euro 6, EPA Tier 4).

Industrial: Used in diesel-powered generators, construction equipment, and agricultural machinery.

Marine: Applied in diesel engines for ships and boats.

Emission Reduction:

Effectively reduces PM, CO, and HC emissions, helping vehicles and equipment comply with environmental regulations.

Improved Air Quality:

Reduces the release of harmful pollutants into the atmosphere.

Energy Efficiency:

Low pressure drop ensures minimal impact on engine performance and fuel efficiency.

Long Service Life:

Durable materials and regeneration capabilities extend the filter's lifespan.

Clogging:

If regeneration is insufficient, the filter can become clogged, leading to increased backpressure and reduced engine performance.

Ash Accumulation:

Non-combustible ash from engine oil and fuel additives can accumulate over time, requiring periodic cleaning or replacement.

Cost:

DPFs are expensive components, and maintenance or replacement can add to operational costs.

DOCs are often installed upstream of the DPF to oxidize CO and HC into less harmful substances like CO₂ and H₂O.

This combination further enhances the overall efficiency of the emission control system.

Honeycomb Ceramic DPFs play a crucial role in reducing air pollution from diesel engines, contributing to cleaner air and improved public health.

They are essential for meeting global emission standards, such as Euro 6 in Europe and EPA Tier 4 in the United States.

Specification

Terms | Unit | Value | Measured value | Test method |

Cordierite main crystalline phase content | % | ≥90.0 | 93.8 | XRD |

AL2O3 | % | 35.4±1.5 | 36.2 | chemical analysis |

MgO | % | 13.5±1.6 | 14.6 | |

SiO2 | % | 49.7±1.7 | 48 | |

volume-weight | Kg/L | ≤0.60 | 0.59 | Culculate(weight/volume) |

Strength | Mpa | ≥15.0 | 28 | Digital display engineering ceramics strength tester |

Mpa | ≥2.0 | 4.5 | ||

Mpa | ≥0.15 | 0.28 | ||

Coefficient of thermal expansion(indoor temperature-800℃) | /℃ | ≤1.8×10-6 | 1.55 | Thermal expansion coefficient apparatus |

Softening point | ℃ | ≥1360 | 1390 | DMTA |

Resistance to heat shocks(550℃) | Time | ≥3 | 3 | muffle furnace |

Water absorption | % | 18-28 | 25 | balance |

Products size

Product Process

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

<< Previous page

Next page >>