Honeycomb ceramic for RTO

*As heat exchange media, ceramic honeycomb materials are mainly utilized in heat recovery unit of RTO s instead of ceramic saddles.

*As filtrate substrate, ceramic honeycomb materials are generally utilized in food processing, environmental industry, metallurgical industry etc. for filtering particulate in industrial waste gas and bubble in liquid of molten melt and making the molten melt laminar so as to increase casting yields, also filtering impurities in juice, dextrose and sucrose etc.

Quick Details

Heat Storage and Transfer:

The honeycomb ceramic acts as a heat exchanger, absorbing heat from the hot exhaust gases and transferring it to the incoming cooler gases.

This process allows the RTO to achieve high thermal efficiency (typically 95% or higher).

Structure:

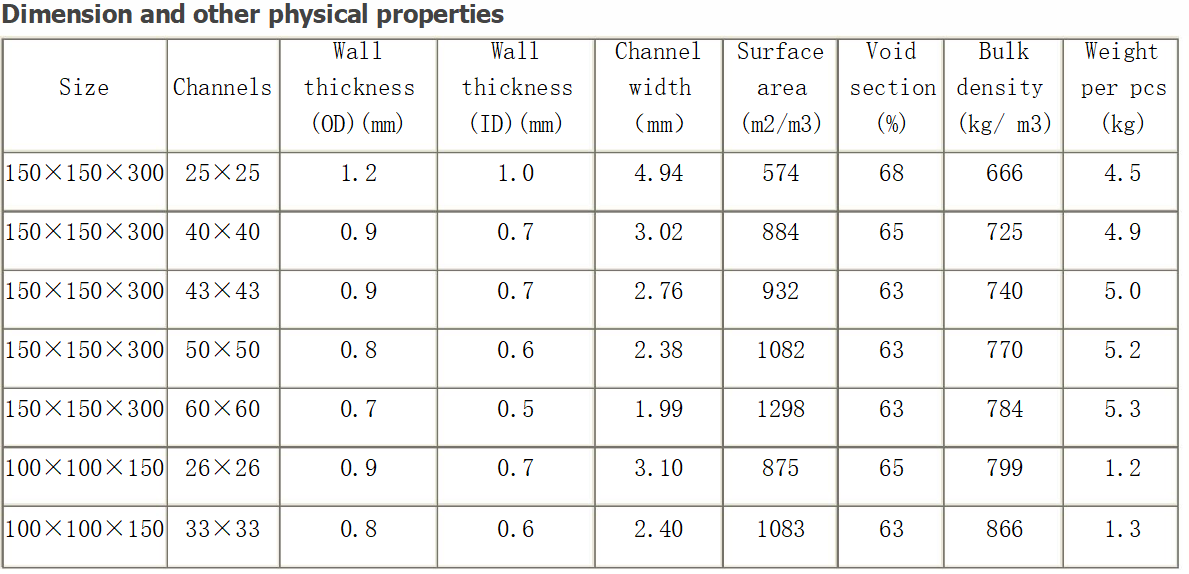

The ceramic is designed in a honeycomb pattern, which provides a large surface area for heat exchange while maintaining low pressure drop.

The channels in the honeycomb structure allow gases to flow through efficiently.

Material:

Made from high-quality, durable ceramic materials such as cordierite or mullite, which can withstand high temperatures (up to 1,000°C or higher) and thermal cycling.

Thermal Efficiency:

The honeycomb ceramic's ability to store and release heat significantly reduces the fuel consumption required to maintain the oxidation temperature, making RTOs energy-efficient.

Gas Flow:

The polluted gas stream passes through one of the ceramic-filled chambers in the RTO, where the ceramic absorbs heat from the hot gases.

Oxidation:

The gas is then directed to the combustion chamber, where VOCs are oxidized at high temperatures (typically 760°C to 1,000°C).

Heat Recovery:

The cleaned, hot gas exits through another ceramic chamber, transferring its heat to the ceramic media.

Cycle Reversal:

The flow direction is periodically reversed to ensure continuous heat recovery and efficient operation.

High Thermal Efficiency:

Enables heat recovery efficiencies of up to 95%, reducing operating costs.

Low Pressure Drop:

The honeycomb structure minimizes resistance to gas flow, reducing energy consumption.

Durability:

Resistant to thermal shock, chemical corrosion, and high temperatures.

Compact Design:

The high surface area-to-volume ratio allows for a compact RTO design.

Environmentally Friendly:

Helps achieve high destruction efficiency (up to 99%) of VOCs and HAPs.

Chemical manufacturing

Pharmaceutical production

Paint and coating industries

Food processing

Printing and packaging

Semiconductor manufacturing

Material Quality:

Ensure the ceramic material is suitable for the specific operating conditions (e.g., temperature, chemical composition of the gas stream).

Cell Density:

Higher cell density provides more surface area but may increase pressure drop.

Maintenance:

Regular inspection and cleaning are required to prevent clogging and maintain efficiency.

In summary, honeycomb ceramic is a vital component in RTO systems, enabling efficient and cost-effective destruction of harmful pollutants while minimizing energy consumption. Its unique structure and material properties make it ideal for high-temperature thermal oxidation processes.

<< Previous page

Next page >>