Ceramic Honeycomb Catalyst Substrate Universal Catalytic Converter For Car Exhaust

A Ceramic Honeycomb Catalyst Substrate is a key component in universal catalytic converters, which are used to reduce harmful emissions from internal combustion engines. These substrates are made from ceramic materials, typically cordierite (2MgO·2Al₂O₃·5SiO₂), and feature a honeycomb structure that provides a high surface area for catalytic reactions. They are widely used in automotive, industrial, and stationary applications to convert toxic gases like carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) into less harmful substances such as carbon dioxide (CO₂), water (H₂O), and nitrogen (N₂).

Quick Details

which are used to reduce harmful emissions from internal combustion engines. These substrates are made from ceramic materials, typically cordierite (2MgO·2Al₂O₃·5SiO₂), and feature a honeycomb structure that provides a high surface area for catalytic reactions. They are widely used in automotive, industrial, and stationary applications to convert toxic gases like carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) into less harmful substances such as carbon dioxide (CO₂), water (H₂O), and nitrogen (N₂).

High Surface Area:

The honeycomb structure provides a large surface area for catalytic reactions, improving the efficiency of emissions reduction.

Thermal Stability:

Ceramic materials like cordierite can withstand high temperatures (up to 1000°C or more) encountered in exhaust systems.

Low Thermal Expansion:

Cordierite has a low coefficient of thermal expansion, making it resistant to thermal shock and cracking.

Chemical Resistance:

Resists corrosion and chemical degradation from exhaust gases and catalytic coatings.

Low Pressure Drop:

The open honeycomb design minimizes resistance to exhaust gas flow, reducing backpressure on the engine.

Lightweight:

Ceramic substrates are lighter than metallic alternatives, contributing to overall vehicle efficiency.

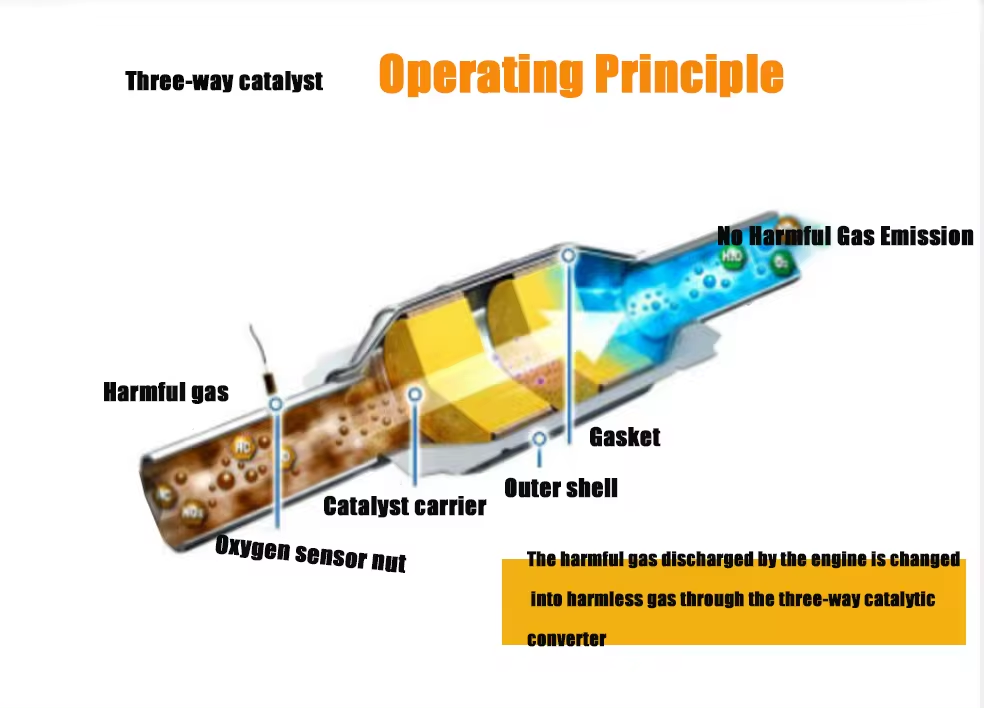

Exhaust Gas Flow:

Exhaust gases containing CO, HC, and NOx pass through the honeycomb structure.

Catalytic Reaction:

Oxidation of CO and HC:

2CO+O2→2CO2

CxHγ+(x+y/4)O2→xCO2+(y/2)H2O

Reduction of NOx:

2NOx→xO2+N2

The substrate is coated with a catalyst (e.g., platinum, palladium, rhodium) that facilitates the following reactions:

Emission Reduction:

Harmful gases are converted into less harmful substances before being released into the atmosphere.

Automotive Catalytic Converters:

Used in gasoline and diesel vehicles to meet emissions standards (e.g., Euro 6, EPA Tier 3).

Motorcycles and Small Engines:

Installed in two-wheelers and small engines to reduce emissions.

Industrial Applications:

Used in generators, forklifts, and other industrial equipment.

Stationary Sources:

Applied in power plants and factories to control emissions.

High Efficiency:

Effectively reduces CO, HC, and NOx emissions.

Durability:

Resists thermal shock, vibration, and chemical degradation.

Cost-Effective:

Ceramic materials are less expensive than metallic alternatives.

Lightweight Design:

Reduces the overall weight of the catalytic converter.

Versatility:

Suitable for a wide range of applications and engine types.

Material Preparation:

Cordierite or other ceramic materials are mixed with binders and additives to form a slurry.

Extrusion:

The slurry is extruded into a honeycomb structure with precise cell density and wall thickness.

Drying and Firing:

The extruded honeycomb is dried and fired at high temperatures to achieve the desired strength and stability.

Catalyst Coating:

The honeycomb is coated with a washcoat (e.g., alumina) and catalytic materials (e.g., platinum, palladium, rhodium) using techniques like impregnation or dip-coating.

Quality Control:

The final product is tested for durability, thermal stability, and catalytic performance.

Cell Density:

Higher cell density (e.g., 400-900 cells per square inch) increases surface area but may increase pressure drop.

Wall Thickness:

Thinner walls improve flow efficiency but may reduce mechanical strength.

Catalyst Type:

Precious metals (e.g., platinum, palladium, rhodium) or non-precious metals (e.g., copper, iron) depending on the application.

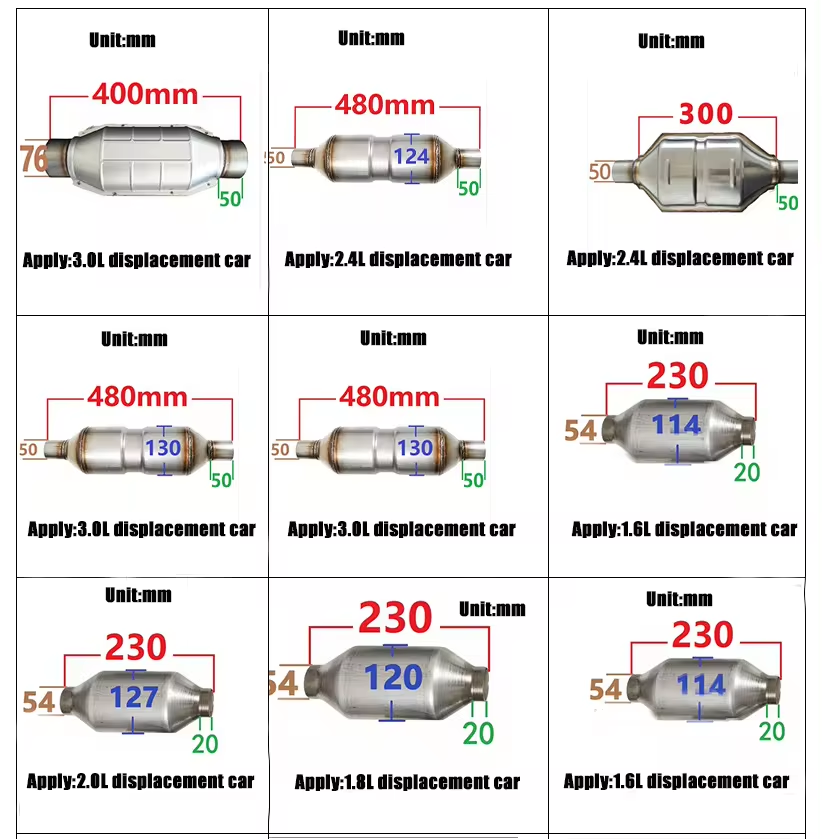

Size and Shape:

Customized to fit specific exhaust systems and applications.

Property

| Ceramic Honeycomb Substrate | Metallic Substrate | |

Material | Cordierite, alumina, etc. | Stainless steel, alloys |

Thermal Conductivity | Lower | Higher |

Mechanical Strength | Lower | Higher |

Weight | Lighter | Heavier |

Cost | Lower | Higher |

Applications | Automotive, light-duty | Heavy-duty, high-temperature industrial |

Ceramic honeycomb catalyst substrates are essential components in universal catalytic converters, offering high efficiency, durability, and cost-effectiveness. Their unique honeycomb structure, combined with advanced catalytic coatings, enables the reduction of harmful emissions from a wide range of engines and industrial processes. By converting toxic gases into harmless substances, these substrates play a critical role in reducing air pollution and meeting environmental regulations.

Specification

Terms | Unit | Value | Measured value | Test method |

Cordierite main crystalline phase content | % | ≥90.0 | 93.8 | XRD |

AL2O3 | % | 35.4±1.5 | 36.2 | chemical analysis |

MgO | % | 13.5±1.6 | 14.6 | |

SiO2 | % | 49.7±1.7 | 48 | |

volume-weight | Kg/L | ≤0.60 | 0.59 | Culculate(weight/volume) |

Strength | Mpa | ≥15.0 | 28 | Digital display engineering ceramics strength tester |

Mpa | ≥2.0 | 4.5 | ||

Mpa | ≥0.15 | 0.28 | ||

Coefficient of thermal expansion(indoor temperature-800℃) | /℃ | ≤1.8×10-6 | 1.55 | Thermal expansion coefficient apparatus |

Softening point | ℃ | ≥1360 | 1390 | DMTA |

Resistance to heat shocks(550℃) | Time | ≥3 | 3 | muffle furnace |

Water absorption | % | 18-28 | 25 | balance |

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

<< Previous page

Next page >>