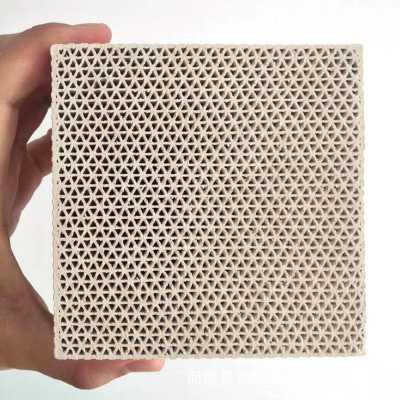

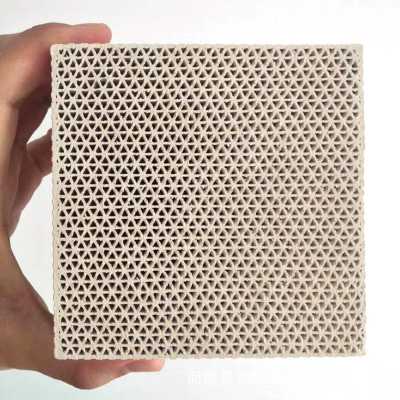

Honeycomb Ceramic Monolith Coated With Zeolite Molecular Sieve for VOC Removal and Adsorption

| Product Name | Honeycomb Zeolite Molecular Sieve |

|---|---|

| Specifications | Full range of sizes, custom orders supported |

| Material | Inorganic microporous material composed of SiO₂, Al₂O₃, and alkali/alkaline earth metals |

| Packaging | Strapped with tank film/palletized, carton, or sealed wooden case |

| Brand | Zhongci |

Quick Details

Honeycomb zeolite molecular sieve is widely used in automobile spraying industry, printing industry, pharmaceutical industry, coating industry, electronic industry, coal chemical industry and so on. It can absorb benzene series, such as toluene, xylene, trimethylbenzene; esters, such as ethyl acetate; alkanes; alcohols; ammonia; hydrogen sulfide; methylaldehyde and most of the VOCs gases.

Honeycomb zeolite molecular sieve can be used for adsorption and concentration of different types of VOCs gas. It can be divided into extrusion molding and carrier coating according to different production process.

Extruded honeycomb zeolite molecular sieve

Extruded honeycomb zeolite molecular sieve is extruded molding from hydrophobic zeolite by adding binder. Compared with the coated honeycomb zeolite, it has the characteristics of large adsorption capacity, fast adsorption rate and high effective adsorption capacity. According to the customer's demand for VOCs gas to be adsorbed, different honeycomb zeolite molecular sieve can be customized.

Coated honeycomb zeolite molecular sieve

Coated honeycomb zeolite is prepared by using honeycomb ceramic as carrier and molecular sieve coating material as the second carrier with a stable structure. It has good hydrophobic properties. The hydrophobic molecular sieves with high Si/Al ratio do not adsorb water molecules in the air and selectively adsorb VOCs. The single-stage adsorption efficiency can reach 90-98%, and it still has strong adsorption capacity at higher temperature.

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Dimensions: | 100×100×50mm (honeycomb), 100×100×100mm (±3mm), etc. | Open Porosity: | 60%-65% |

| Appearance: | White block, square/triangular/hexagonal channels | Geometric Surface Area: | 600-1800 m²/m³ |

| Composition: | Silico-aluminate | Specific Heat Capacity: | 0.85-0.87 kJ/(kg·K) |

| Bulk Density: | 370-550 kg/m³ | Axial Compressive Strength: | >1.0 MPa |

| Max. Temperature: | 650°C | Radial Compressive Strength: | >0.3 MPa |

| Zeolite Powder BET: | ≥700 m²/g | Adsorption Temp.: | ≤60°C |

| Operating Space Velocity: | 8000-10000 h⁻¹ | Desorption Temp.: | 160-260°C |

| Optimal Adsorption Temp.: | ≤40°C (lower = better adsorption) | Typical Space Velocity: | 5000-10000 h⁻¹ |

| Desorption Temp.: | 160-210°C (adjust based on VOCs type) | Features: | Thin walls, high porosity, excellent strength, low pressure drop, direct replacement for honeycomb activated carbon. |

<< Previous page

Next page >>