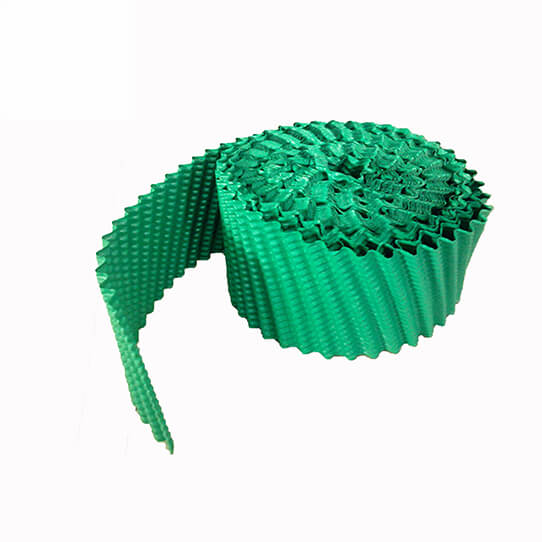

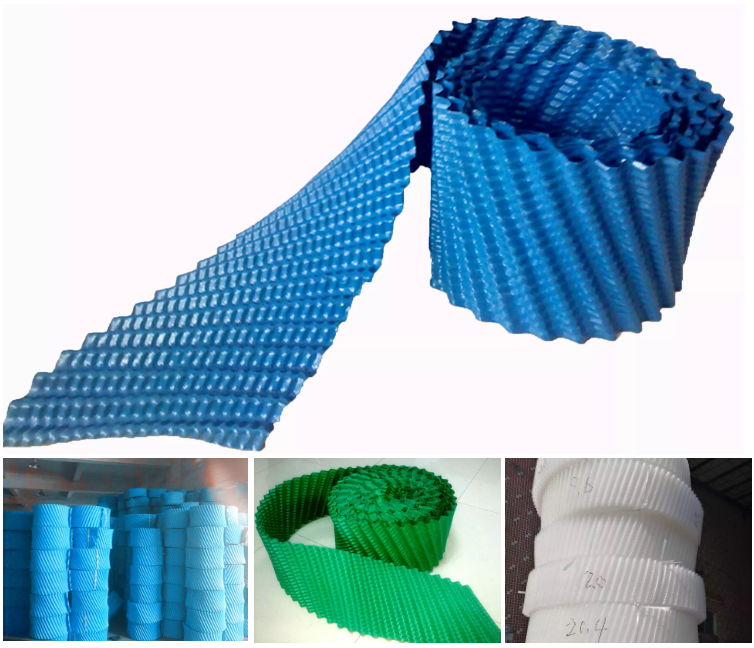

Round Counterflow Cooling Tower PVC Fill

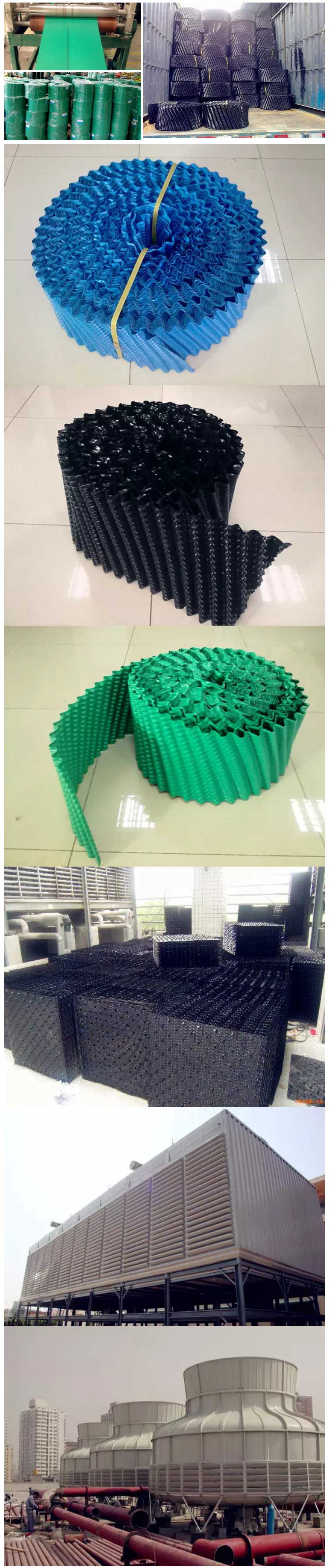

The round counterflow cooling tower fill is also called "obliquely staggered cooling tower fill", it is made from modified flat PVC sheets through hot-pressing processing. The role of the water-spraying fill is to transfer the hot water needs to be cooled into water drops and to mold the water film, so as to increase the contact area and time of water and air, i.e., increase the heat transfer intensity of water and air. The cooling process of water mainly occurs in the water-spraying fill, where the heat transfer and mass transfer of water and air occur. The cooling effect of cooling tower depends on the heat transfer performance of the water-spraying fill to a very large extent. The water-spraying fill with good performance owns quite good heat dissipation capability. The obliquely staggered fill has advanced technology, reasonable design, reliable data, and durabilities. According to the test and long-term operation, the cooling effect is very good, and it owns such advantages as small ventilation resistance,strong hydrophilia, large contact area, etc. The inclination angle usually is 60 degrees, and it is mainly applied to the round counterflow cooling tower

Quick Details

Applicable Industries: Manufacturing Plant

Showroom Location: None

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: Ordinary Product

Warranty of core components: 1 Year

Core Components: Filling

Condition: New

Cooling Type: Cross Flow

Material: PP

Place of Origin: China

Brand Name: Zhongci

Voltage: /

Power: /

Dimension(L*W*H): /

Weight: 1.55 KG

Warranty: 3 years

Key Selling Points: Long Service Life

Width: 305mm 610mm

Product name: cooling tower infill

Sheet thickness: 0.25-0.4mm

Color: Black White

The Round Counterflow Cooling Tower Fill, also known as Obliquely Staggered Cooling Tower Fill, is a high-performance cooling media made from modified flat PVC sheets through hot-pressing processing. This water-spraying fill plays a crucial role in enhancing heat transfer efficiency by increasing the contact area and interaction time between water and air.

Enhanced Heat Transfer Efficiency

Promotes water film formation and droplet dispersion, maximizing air-water interaction.

High Cooling Performance

The cooling process primarily occurs within the fill, where both heat transfer and mass transfer take place.

Low Ventilation Resistance & High Hydrophilicity

Ensures efficient airflow, improving overall cooling tower performance.

Durable & Long-Lasting Material

Made from high-quality PVC, ensuring weather resistance and long service life.

Optimized Design for Maximum Contact Area

Features an inclination angle of 60 degrees, providing a large surface area for effective cooling.

Round Counterflow Cooling Towers

Industrial Cooling & HVAC Systems

Power Plants & Petrochemical Industries

Steel Mills & Chemical Processing Plants

Details Images

Recommend Products

Manufacturing Technique

<< Previous page

Next page >>