Carbon Molecular Sieve

Molecular Sieve takes the appearance of cylindrical black solid, contains countless 4 angstrom fine pores. It can be used to separate air into nitrogen and oxygen. In industry, CMS can concentrate nitrogen from air with PSA systems, up to 98%~99.999% N2 purity. Our CMS products have the character of large nitrogen yield capacity; high nitrogen recovery. It can meet the requirement of all types of PSA nitrogen systems. The carbon molecular sieve is widely applied in petroleum chemical industry, the heat treatment of metal, the electronic manufacture and food preservation industries.

Quick Details

Microporous Structure:

CMS has a network of micropores (pore size < 2 nm) that selectively adsorb smaller gas molecules while excluding larger ones.

High Adsorption Capacity:

The large surface area (typically 500-1500 m²/g) allows for high adsorption of target gases.

Selective Adsorption:

CMS can separate gases based on differences in molecular size, kinetic diameter, and adsorption rates.

Thermal and Chemical Stability:

Resists high temperatures and harsh chemical environments, making it suitable for industrial applications.

Regenerability:

CMS can be regenerated by pressure swing adsorption (PSA) or temperature swing adsorption (TSA) processes, allowing for repeated use.

Adsorption:

Gas molecules are adsorbed onto the surface of the CMS pores based on their size and affinity.

Separation:

Smaller molecules (e.g., oxygen, nitrogen) are adsorbed more quickly or strongly than larger molecules (e.g., methane, carbon dioxide).

Desorption:

Adsorbed gases are released by reducing pressure (PSA) or increasing temperature (TSA), regenerating the CMS for reuse.

Nitrogen Generation (PSA Systems):

CMS is widely used in pressure swing adsorption (PSA) systems to produce high-purity nitrogen from air.

Oxygen and other gases are adsorbed, while nitrogen passes through.

Hydrogen Purification:

Used to separate hydrogen from gas mixtures (e.g., syngas, refinery off-gases).

Natural Gas Processing:

Removes impurities like carbon dioxide, water vapor, and heavier hydrocarbons from natural gas.

Biogas Upgrading:

Separates methane from carbon dioxide in biogas to produce renewable natural gas (RNG).

Air Drying:

Removes moisture from compressed air streams.

Oxygen Enrichment:

Used in medical and industrial applications to produce oxygen-enriched air.

High Selectivity:

Effectively separates gases based on molecular size and adsorption kinetics.

Cost-Effective:

Lower operating costs compared to cryogenic distillation or membrane separation.

Compact Design:

PSA systems using CMS are compact and require less space.

Energy Efficiency:

Lower energy consumption compared to traditional separation methods.

Regenerability:

Can be regenerated and reused multiple times, reducing waste.

Model | Carbon Molecular Sieve | |||

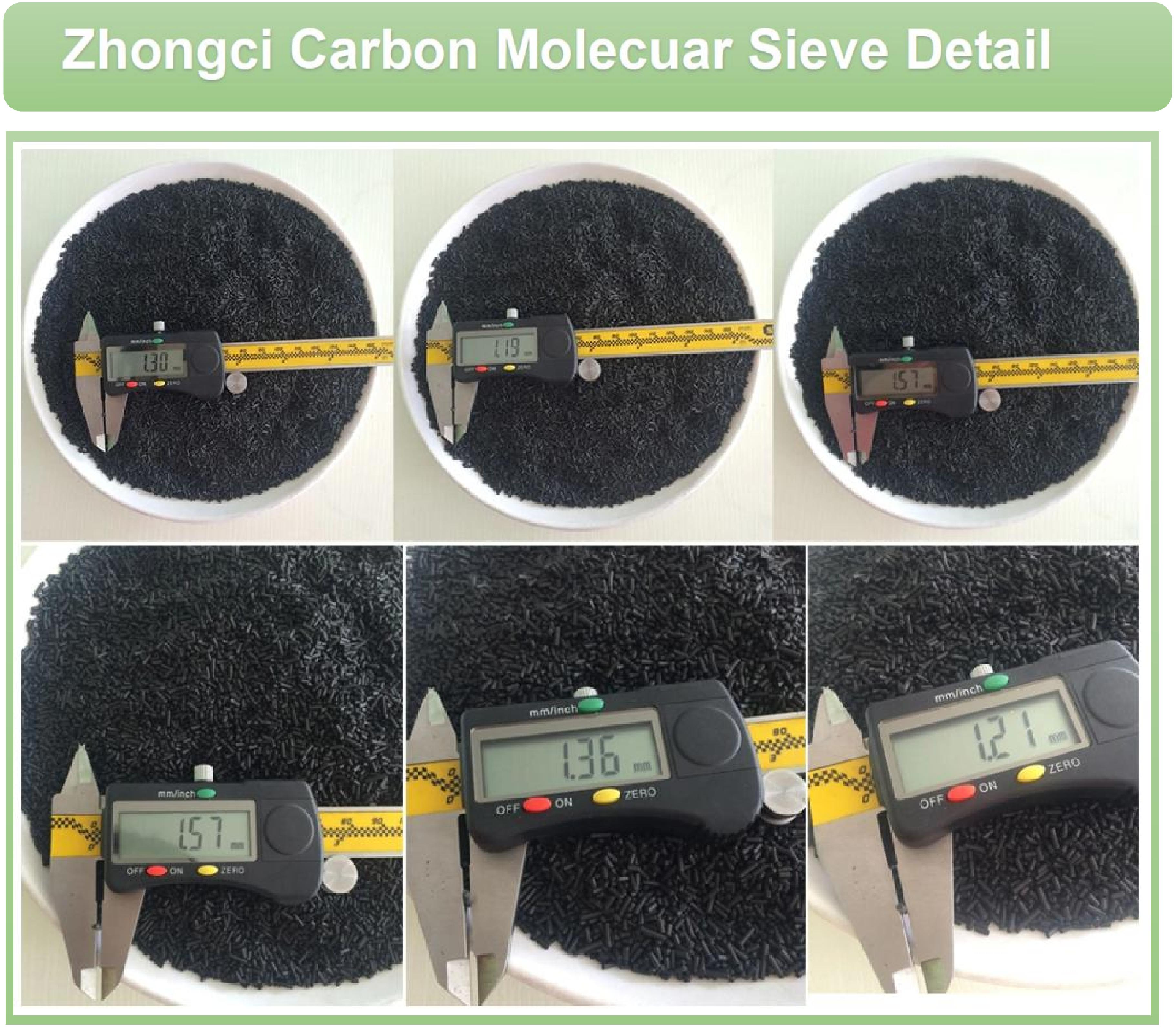

Appearance | Black, extruded(pellet) | |||

Nominal pore diameter | 4 angstroms | |||

Diameter (mm) | 0.95mm, 1.1-1.3mm, 1.3-1.5mm, 1.5-1.8mm | |||

Crushing strength (The test temperature≤20℃) | >50 N/PC | |||

Bulk Density | 630-680 KG/M3 | |||

Dust level | 100PPM Max | |||

Adsorbent time (S) (The test temperature≤20℃) | 2*50(can be adjusted) | |||

Type | Adsorption Pressure (MPa) | N2 Purity(%) | N2 quantity (M3/T.MT) | Air/N2 (%) |

CMS-220 |

0.75-0.8 | 99.999 | 55 | 6.8 |

99.99 | 100 | 4.8 | ||

99.9 | 145 | 3.7 | ||

99.5 | 220 | 2.6 | ||

CMS-240 |

0.75-0.8 | 99.999 | 65 | 6.6 |

99.99 | 110 | 4.6 | ||

99.9 | 160 | 3.5 | ||

99.5 | 240 | 2.5 | ||

CMS-260 |

0.75-0.8 | 99.999 | 75 | 6.5 |

99.99 | 120 | 4.6 | ||

99.9 | 175 | 3.4 | ||

99.5 | 260 | 2.3 | ||

CMS-280 |

0.75-0.8 | 99.999 | 90 | 6.4 |

99.99 | 135 | 4.5 | ||

99.9 | 190 | 3.4 | ||

99.5 | 280 | 2.3 | ||

<< Previous page

Next page >>