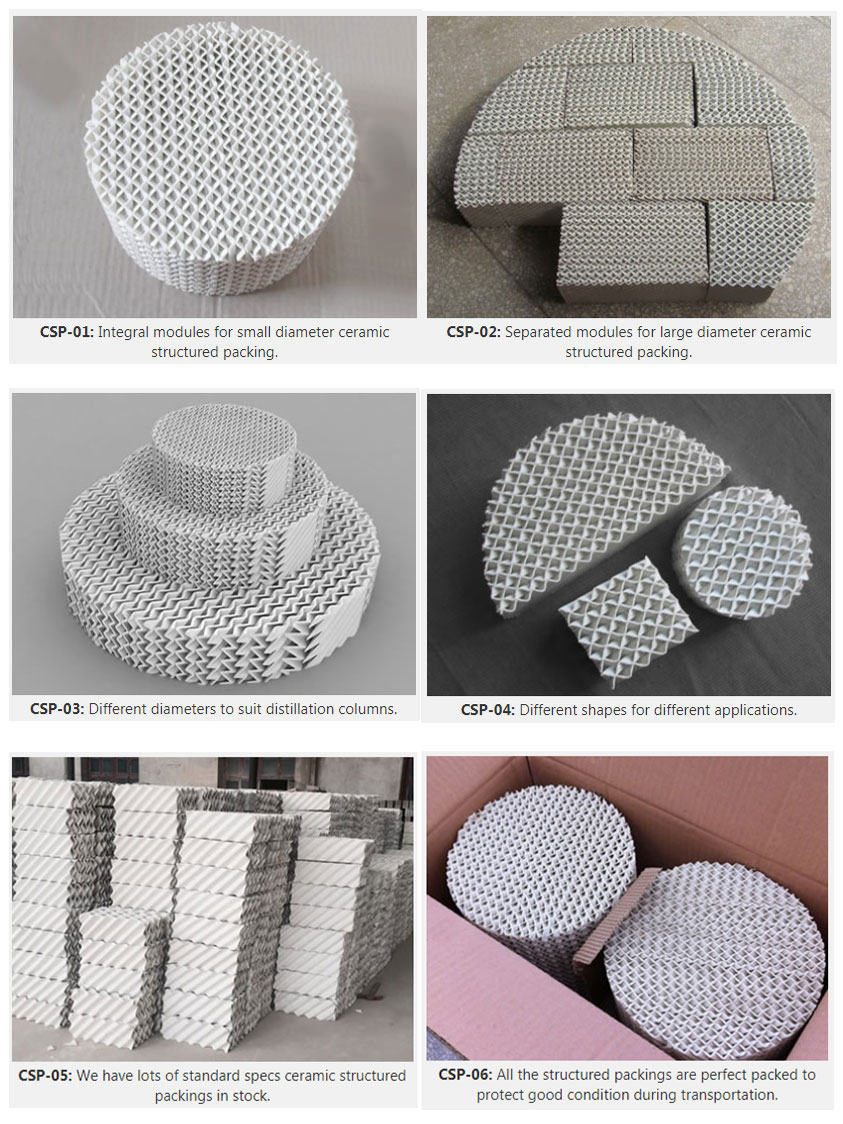

Ceramic structured packing

Advantages

High capacity.

High separation efficiency.

Low pressure drop.

Large flexibility.

Corrosion and rust resistance.

Alkali and acid resistance.

Applications

Rectify organic halide.

Rectify and absorb some corrosive mixtures/

Absorb nitric acid and concentrated sulfuric acid and purify the chemical air.

Used as catalyst carrier in heat exchanger.

Quick Details

Ceramic Structured Packing is a high-performance mass transfer material used in distillation, absorption, and stripping columns. It is made from high-purity ceramic and features a structured, corrugated design that maximizes gas-liquid contact, improves mass transfer efficiency, and minimizes pressure drop.

High Mass Transfer Efficiency

The structured, corrugated geometry ensures uniform gas-liquid distribution and enhanced separation performance.

Excellent Corrosion & Thermal Resistance

Withstands acidic, alkaline, and high-temperature environments, making it suitable for chemical processing.

Low Pressure Drop & Energy Savings

Open channels reduce resistance to gas flow, improving efficiency and reducing operational costs.

Good Wettability & Large Surface Area

Promotes efficient mass transfer by maintaining consistent liquid film flow.

High Mechanical Strength & Durability

Resistant to mechanical stress, ensuring long service life in demanding applications.

Chemical & Petrochemical Industries

Used in acid gas removal, solvent recovery, and fine chemical production.

Sulfuric Acid & Nitric Acid Production

Ideal for absorbers, scrubbers, and reaction towers.

Distillation & Separation Processes

Enhances separation efficiency in pharmaceutical, petrochemical, and industrial processing.

Environmental Protection & Gas Treatment

Applied in flue gas desulfurization (FGD), air purification, and wastewater treatment.

Table 1: Chemical Composition of Ceramic Structured Packing | |||||

SiO2 | Fe2O3 | CaO | Al2O3 | MgO | Other |

≥72% | ≤0.5% | ≤1.0% | ≥23% | ≤1.0% | 2% |

Table 2: Common Specs of Ceramic Structured Packing | |||||

Item | Model | Specific Surface | Bulk Density | Voidage Ratio | Pressure Drop |

(m2/m3) | (kg/m3) | (%) | (mmHg/m) | ||

CSPS-01 | 125Y | 125 | 320 | 90 | 1.8 |

CSPS-02 | 160Y | 160 | 370 | 85 | 2 |

CSPS-03 | 250Y | 250 | 420 | 80 | 2 |

CSPS-04 | 350Y | 350 | 170 | 78 | 2.5 |

CSPS-05 | 400Y | 400 | 500 | 75 | 3 |

CSPS-06 | 450Y | 450 | 520 | 72 | 4 |

CSPS-07 | 550Y | 550 | 620 | 74 | 5.5 |

CSPS-08 | 700Y | 700 | 650 | 72 | 6 |

CSPS-09 | 100X | 100 | 280 | 92 | 1.5 |

CSPS-10 | 125X | 125 | 300 | 90 | 1.8 |

CSPS-11 | 160X | 160 | 350 | 85 | 2 |

CSPS-12 | 250X | 250 | 380 | 80 | 2.5 |

CSPS-13 | 350X | 350 | 450 | 78 | 3 |

CSPS-14 | 400X | 400 | 480 | 75 | 4 |

CSPS-15 | 450X | 450 | 500 | 72 | 4.5 |

CSPS-16 | 470X | 470 | 440 | 75 | 5 |

CSPS-17 | 550X | 550 | 620 | 74 | 5.5 |

CSPS-18 | 700X | 700 | 650 | 72 | 6 |

<< Previous page

Next page >>