Plastic Pall Ring with High Mass Transfer Velocity

Plastic pall ring is also called plastic pall ring packing. It is a type of random packing, which modifies directly at the shortcomings of raschig ring. This type pall ring makes some structural improvements on the basis of raschig ring. It adds many small rectangular windows on its wall. The blades of these small rectangular windows join together in the center of the pall ring. The openings on plastic pall ring's lateral wall fully utilize its internal surface area and greatly increase the gas-liquid agitation. Therefore, plastic pall ring has better gas-liquid distribution performance than plastic raschig ring.

Plastic pall ring is characterized by high gas velocity, small resistance and large production capacity. It performs well in stripping and scrubbing. This kind pall ring packing has good chemical resistance, it is suitable for various industries, such as chlor-alkali industry, gas industry and chemical industry. It is widely used in carbon dioxide degassing towers, ozone exposure reaction towers, vacuum distillation towers and other reaction towers.

Quick Details

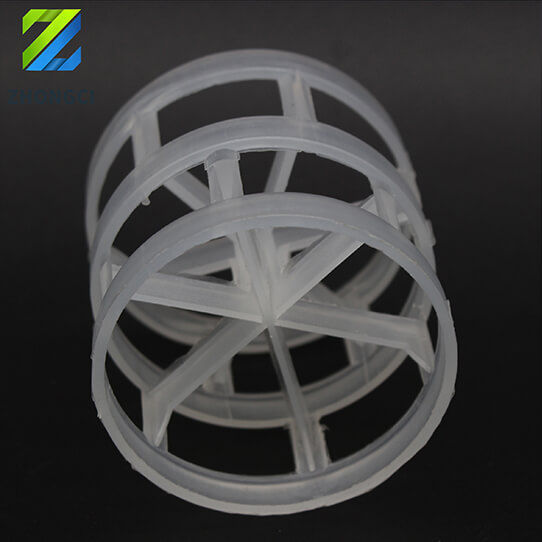

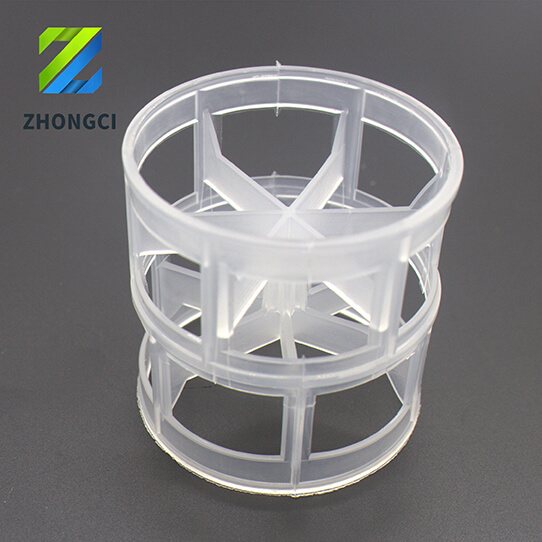

ZC-01: 360° shows of plastic pall ring for comprehensive understanding.

ZC-02: The rectangular openings of plastic pall ring largely increase its internal surface area and mass transfer velocity.

The Plastic Pall Ring, also known as Plastic Pall Ring Packing, is a widely used random tower packing designed to improve upon the limitations of the Raschig Ring. By incorporating window-like openings on its cylindrical structure, the Pall Ring enhances gas-liquid distribution, increases mass transfer efficiency, and reduces pressure drop.

Improved Design

The open structure with multiple windows increases surface area and promotes better gas-liquid interaction compared to the Raschig Ring.

High Void Fraction

Provides low-pressure drop, ensuring efficient fluid flow and energy savings in industrial processes.

Excellent Chemical Resistance

Made from corrosion-resistant plastics such as PP (Polypropylene), PE (Polyethylene), PVC (Polyvinyl Chloride), and PVDF (Polyvinylidene Fluoride), making it suitable for acidic, alkaline, and corrosive environments.

Lightweight & Cost-Effective

Easier to handle, install, and maintain compared to metal or ceramic alternatives.

Good Mechanical Strength & Durability

Resistant to impact, aging, and wear, ensuring long service life in harsh conditions.

Due to its high efficiency and chemical resistance, Plastic Pall Rings are widely used in:

Gas Scrubbing & Absorption Towers

Cooling Towers

Distillation & Stripping Columns

Waste Gas Treatment & Desulfurization

Water & Wastewater Treatment

● Material: PE (polyethylene), PP (polypropylene), RPP (reinforced polypropylene), PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride) and PVDF (polyvinylidene fluoride).

● Lifespan: more than 3 years.

● Package: plastic bags, ton bags.

Table 1: The Technical Parameter of Plastic Pall Ring | ||||||

Item | Size | Surface Area | Voidage | Bulk Number | Bulk Density | Dry Packing Factor |

ZC-01 | 16 × 16 × 1 | 188 | 91% | 170000 | 85 | 275 |

ZC-02 | 25 × 25 × 1.2 | 175 | 90% | 53500 | 69 | 239 |

ZC-03 | 38 × 38 × 1.4 | 115 | 89% | 15800 | 69 | 220 |

ZC-04 | 50 × 50 × 1.5 | 93 | 90% | 6500 | 52 | 127 |

ZC-05 | 76 × 76 × 2.6 | 73.2 | 92% | 1927 | 48 | 94 |

ZC-06 | 100 × 100 × 3 | 52.8 | 94% | 1000 | 48 | 82 |

Features:

● Good heat resistance.

● Large internal surface area.

● Effective mass transfer velocity.

● Good chemical resistance.

● High operating flexibility.

● Cost effective.

Applications:

● Applied in various mass transfer towers for stripping, scrubbing and absorption.

● Used in the industries of chemical, gas, petroleum, chlor-alkali and environmental protection.

● Used in carbon dioxide degassing towers, ozone exposure reaction towers, vacuum distillation towers and other reaction towers.

<< Previous page

Next page >>