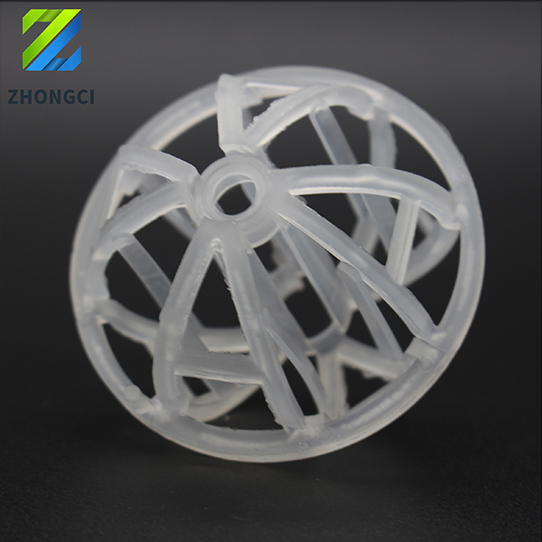

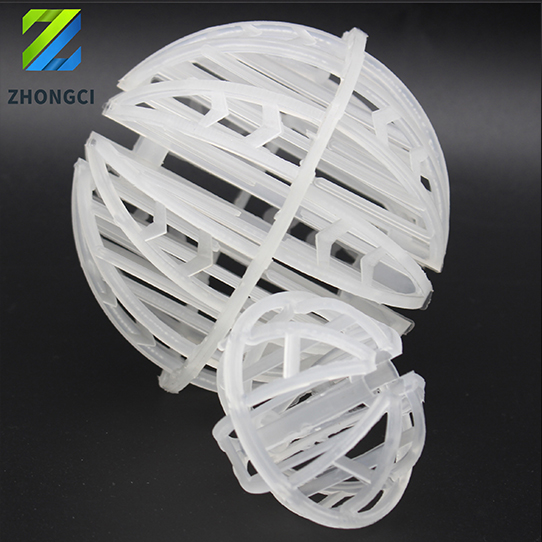

Plastic Tri-Pack

Features of plastic tri-pack

• High mass transfer efficiency.

• Evenly gas and liquid distribution.

• High surface area.

• Extremely low pressure drop.

• Temperature and chemical resistance.

Applications of plastic tri-pack

• Gas absorption and purification.

• Gas & liquid separation.

• Liquid extraction.

• Water treatment.

• Biological filtration.

Quick Details

Plastic Tri-Pack is a hollow, spherical random packing designed to enhance gas-liquid contact in mass transfer applications. Its symmetrical geometry, composed of a network of ribs, struts, and drip rods, ensures maximum surface area and efficient liquid distribution. This structure prevents dry spots and channeling, improving overall scrubbing, absorption, and cooling tower performance.

High Void Space

Ensures low-pressure drop and efficient gas-liquid mixing.

Excellent Liquid Distribution

The unique open structure eliminates nesting and ensures uniform contact.

Superior Chemical & Corrosion Resistance

Available in PP, PE, PVC, PVDF, and other plastic materials, making it ideal for acidic and alkaline environments.

Lightweight & High Mechanical Strength

Injection-molded plastic construction provides durability and easy handling.

Self-Wetting Design

Reduces water retention and improves mass transfer efficiency.

1" (25 mm)

1-1/4" (32 mm)

3" (76 mm)

3-1/2" (89 mm)

Gas Scrubbers & Air Pollution Control

Cooling Towers & Water Treatment Systems

Absorption & Stripping Towers

Chemical & Petrochemical Processing

Waste Gas & VOC Control Systems

Would you like additional information on technical specifications, material selection, or supplier details?

360° shows of plastic tri-pack for comprehensive understanding.

Available materials

Polypropylene (PP).

Polyethylene (PE).

Polyvinyl chloride (PVC).

Chlorinate polyvinyl chloride (CPVC).

Polyvinylidene Fluoride (PVDF).

Reinforced Polypropylene (RPP).

Sectional view of plastic tri-pack.

Side view of plastic tri-pack.

Plastic tri-pack has a hollow spherical structure with several ribs and struts.

Plastic tri-pack can be customized into any size according to customers' requirements.

Table 1: The Specification of Plastic Tri-Pack | ||||||

Item | Size | Surface Area | Voidage | Bulk Number | Bulk Density | Dry Packing Factor |

PTPR-01 | 25 | 85 | 90% | 77000 | 81 | 28 |

PTPR-02 | 32 | 70 | 92% | 25000 | 70 | 25 |

PTPR-03 | 50 | 48 | 93% | 10500 | 62 | 16 |

PTPR-04 | 95 | 38 | 95% | 1800 | 45 | 12 |

Table 2: Physical & Chemical Properties of Different Materials of Plastic Tri-Pack | ||||

Material/Performance | Density | Operation Temperature | Chemical Corrosion Resistance | Compression Strength |

PE | 0.98 | 90 | good | >6.0 |

PP | 0.96 | >100 | good | >6.0 |

RPP | 1.2 | >120 | good | >6.0 |

PVC | 1.7 | >60 | good | >6.0 |

CPVC | 1.8 | >90 | good | >6.0 |

PVDF | 1.8 | >150 | good | >6.0 |

<< Previous page

Next page >>