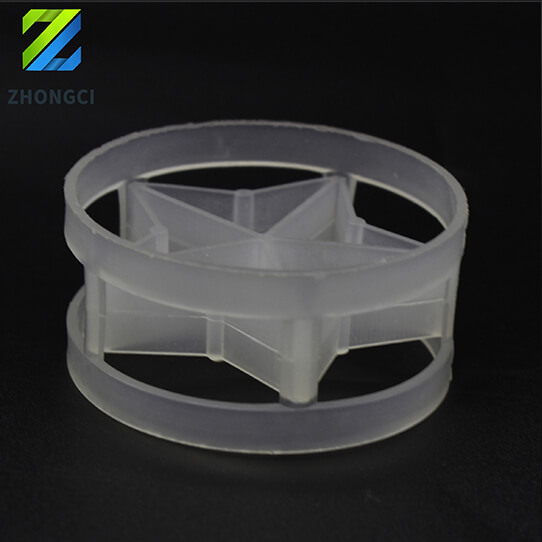

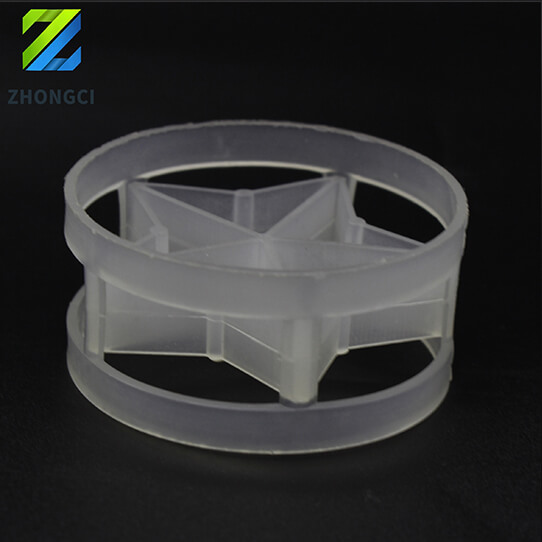

Plastic Super Mini Ring – Corrosion and Temperature Resistant for High Performance

Plastic Super Mini Ring, also called plastic flat ring, is an advanced products of plastic cascade mini ring. In the product design, the plastic super mini ring change the bevel edge of cascade mine ring into flat edge, which can make the structure uniform and improve the bulk density of random packing. Additional, the internal fingers of cascade ring are changed into internal curved rib to increase the packing strength.

The height-diameter ratio of plastic super mini ring is about 0.2–0.4, which has low pressure drop, high flux, excellent treating and mass transfer performance to be used in the water treatment applications.

Quick Details

PPR-02: The rectangular openings of plastic pall ring largely increase its internal surface area and mass transfer velocity.

The Plastic Super Mini Ring is a highly efficient random packing material designed for enhanced gas-liquid contact. Its compact and lightweight design ensures excellent mass transfer performance in various industrial applications.

Optimized Mass Transfer Efficiency – Ensures superior gas-liquid interaction.

Low Pressure Drop – Reduces energy consumption and enhances system efficiency.

High Chemical and Thermal Resistance – Withstands exposure to harsh chemicals and extreme temperatures.

Lightweight and Durable – Reduces tower load while maintaining long-lasting performance.

Enhanced Surface Area – Improves separation and absorption processes.

Used in distillation, absorption, and stripping towers to optimize separation efficiency.

Improves the removal of pollutants in emission control systems.

Enhances fluid distribution in biological and industrial water treatment processes.

Ensures effective heat transfer for high-temperature operations.

Compact Design for Maximum Efficiency – Provides high packing density and optimized performance.

Corrosion and Wear Resistance – Ensures durability in aggressive environments.

Energy-Efficient Operation – Reduces operational costs with lower pressure drop.

Easy Handling and Maintenance – Lightweight structure simplifies installation and replacement.

Choose the Appropriate Size – Select based on process requirements.

Ensure Proper Installation – Distribute evenly for optimal gas-liquid contact.

Monitor Performance Regularly – Conduct periodic inspections to maintain efficiency.

Plastic Super Mini Rings provide an effective and reliable solution for industries requiring high-performance mass transfer and separation. Their compact siz

Specifications:

● Material: PE (polyethylene), PP (polypropylene), RPP (reinforced polypropylene), PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride) and PVDF (polyvinylidene fluoride).

● Lifespan: more than 3 years.

● Package: plastic bags, cartons.

Table 1: Common Specification of Plastic Super Mini Ring | |||||

Item | Size | Surface Area | Voidage | Bulk Number | Dry Packing Factor |

PSMT-01 | 25 × 9 × 1.0 | 160 | 88% | 170000 | 287 |

PSMT-02 | 38 × 13 × 1.2 | 145 | 92% | 460000 | 175 |

PSMT-03 | 50 × 17 × 1.5 | 128 | 93% | 21500 | 140 |

PSMT-04 | 76 × 26 × 2.5 | 116 | 93% | 6500 | 112 |

Features:

● Good heat resistance.

● Large internal surface area.

● Effective mass transfer velocity.

● Good chemical resistance.

● High operating flexibility.

● Cost effective.

Applications:

● Applied in various mass transfer towers for stripping, scrubbing and absorption.

● Used in the industries of chemical, gas, petroleum, chlor-alkali and environmental protection.

● Used in carbon dioxide degassing towers, ozone exposure reaction towers, vacuum distillation towers and other reaction towers.

<< Previous page

Next page >>