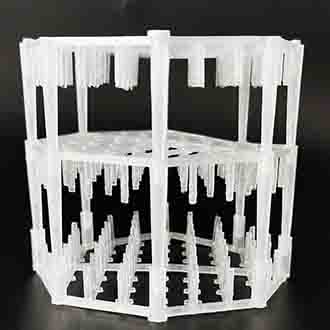

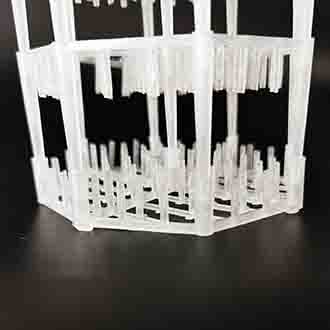

Zhongci Octagonal Plastic Q-pack Tower Packing for Scrubbers

Plastic Q-pack tower packing is a kind of high-capacity plastic random packing. It has a special octagonal structure. This structure has a geometric surface, large holes and a small volume. It can ensure plastic Q-pack's high efficiency in oil-water separation. Plastic Q-pack tower packing has many advantages, such as good plugging resistance, high gas-liquid contacting efficiency, good heat resistance and excellent mass transfer performance. It is suitable for large scrubbers, gas absorbers and coolers.

This type of random packing is easy to operate and install. It has high separation efficiency and low maintenance costs. Plastic Q-pack tower packing is fit for drinking water treatment, wastewater reclamation and biological treatment. It is widely used as filter devices in potable water treatment process, seawater desalination system and VOC (volatile organic compounds) control system.

Quick Details

Plastic Q-pack tower packing has an special octagonal structure.

Plastic Q-Pack is an advanced random tower packing material designed for use in scrubbers, cooling towers, and biological filtration systems. Its unique open structure maximizes gas-liquid contact, ensuring high-efficiency mass transfer and optimal separation performance.

High Surface Area – Enhances gas-liquid interaction for superior scrubbing efficiency.

Low Pressure Drop – Improves airflow and reduces energy consumption.

Durable and Chemical Resistant – Withstands corrosive environments and extreme temperatures.

Lightweight and Easy to Install – Reduces structural load while simplifying handling and maintenance.

Self-Cleaning Design – Prevents clogging and ensures continuous operation.

Enhances removal of pollutants and contaminants in air purification systems.

Optimizes bacterial growth surfaces for wastewater treatment processes.

Improves water distribution and heat exchange efficiency.

Maximizes mass transfer performance in chemical processing industries.

Superior Gas-Liquid Contact Efficiency – Ensures high mass transfer rates.

Corrosion and Wear Resistance – Maintains performance in aggressive conditions.

Energy-Efficient Operation – Lowers pressure drop for reduced operational costs.

Easy Installation and Maintenance – Lightweight design allows for quick replacement and handling.

Select the Right Size and Material – Choose according to specific process requirements.

Ensure Proper Packing Distribution – Evenly distribute for optimal gas-liquid contact.

Regular Monitoring and Maintenance – Periodic checks ensure long-term efficiency and performance.

Plastic Q-Pack Tower Packing is a high-efficiency solution for scrubbers, cooling towers, and filtration systems. Its durable, low-pressure drop, and self-cleaning design make it a preferred choice for industries requiring reliable mass transfer and separation. Invest in Plastic Q-Pack to enhance process performance and ensure long-term operational success.

Specifications:

Plastic tower packing can be made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinyiidene fluoride (PVDF) and Polytetrafluoroethylene (PTFE). The temperature in media ranges from 60 Degree C to 280 Degree C

Plastic Tower Packings: plastic pall ring, plastic saddle, plastic super saddle, plastic cascade ring, plastic conjugate ring, plastic teller rosette ring, plastic hi-flow ring, plastic snowflake ring, plastic VSP ring, plastic tri-pack, etc.

Physical & chemical properties of plastic Random Packing:

| Performance / Material | PE | PP | RPP | PVC | CPVC | PVDF |

| Density (g/cm3) | 0.94-0.96 | 0.89-0.91 | 0.93-0.94 | 1.32-1.44 | 1.50-1.54 | 1.75-1.78 |

| Operation Temp.(oC) | 90 | >100 | >120 | >60 | >90 | >150 |

| Chemical corrosion resistance | Good | Good | Good | Good | Good | Good |

| Compression Strength(Mpa) | >6.0 | >6.5 | >7.0 | >6.0 | >8.0 | >10.0 |

● Lifespan: more than 3 years.

● Package: plastic bags, cartons.

·Size: 82.5 mm × 95 mm.

·Voidage: 96.3%.

·Bulk number: 1165 n/m3.

·Bulk density: 33.7 kg/m3.

·Dry packing factor: 23 m-1.

·Package: plastic bags, cartons.

Features:

·High void fraction.

·Low pressure drop.

·Large gas-liquid contacting surface.

·Fouling and plugging resistance.

·High separation efficiency.

·Convenient maintenance.

Applications:

·Used in drinking water treatment or wastewater reclamation.

·Used in filtration and biological treatment.

·Applied in potable water treatment processes.

·Applied in the field of water purification, petroleum, chemistry, coal gas and environmental protection.

<< Previous page

Next page >>