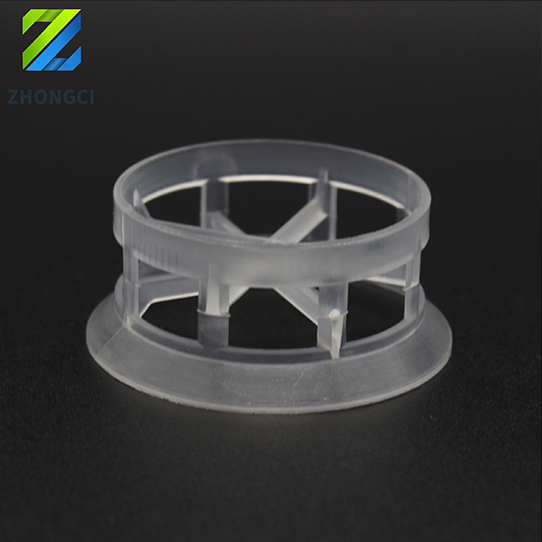

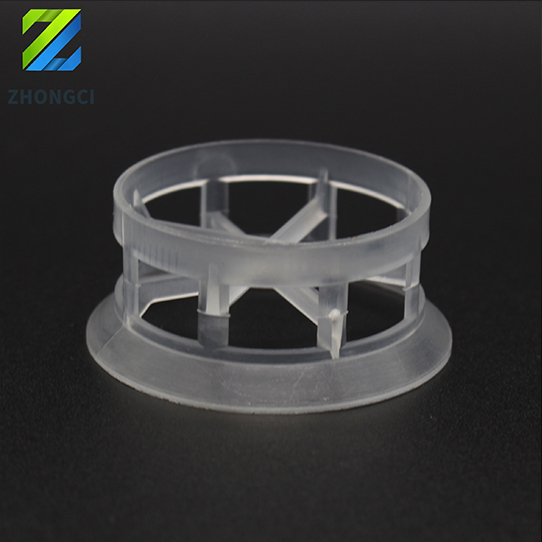

Plastic Cascade Mini Ring with good Fouling Resistance

Plastic cascade mini ring is a type of high performance plastic random packing. Its vertical axis orientation allows more fluids to pass through the cylinder. Solids are easily washed away by the fluids. Therefore, plastic cascade mini ring has good fouling resistance. It is characterized by low aspect ratio, good corrosion resistance and excellent separation effect. Plastic cascade mini ring has larger capacity and higher efficiency than plastic pall ring.

This type of tower packing can be made from various corrosion resistant materials, such as polypropylene, polyethylene and polyvinyl chloride. Compared with metal cascade mini ring, it has better corrosion resistance and lower costs. Plastic cascade mini ring is fit for the desulfurization, decarbonization and crude oil separation system. It is widely used in absorption, extraction, scrubbing, stripping and heat transfer applications.

Quick Details

The unique conical edge design effectively increases the void rate among the random packings in the packed bed.

The Plastic Cascade Mini Ring is a highly efficient random packing material designed to improve gas-liquid contact in industrial processes. Its unique open structure minimizes resistance, enhances mass transfer, and offers excellent fouling resistance, making it ideal for demanding applications.

Optimized Surface Area – Ensures superior gas-liquid interaction for high separation efficiency.

Low Pressure Drop – Reduces energy consumption while maintaining optimal performance.

Excellent Fouling Resistance – Prevents clogging and ensures continuous operation.

Lightweight and Easy to Install – Simplifies handling and system integration.

High Chemical and Thermal Stability – Withstands aggressive industrial environments.

Enhances mass transfer efficiency in chemical, petrochemical, and refining industries.

Improves pollutant removal efficiency in industrial emission treatment systems.

Optimizes liquid distribution and enhances filtration performance.

Ensures efficient cooling and fluid distribution for process optimization.

High Fouling Resistance – Prevents blockages for long-term stability.

Energy-Efficient Design – Lowers pressure drop to reduce operational costs.

Superior Corrosion and Wear Resistance – Maintains durability in harsh conditions.

Efficient and Cost-Effective – Reduces maintenance and replacement frequency.

Select the Appropriate Size – Choose based on process specifications.

Ensure Proper Packing Distribution – Evenly distribute to maximize efficiency.

Perform Regular Inspections – Maintain peak performance with routine monitoring.

Plastic Cascade Mini Rings provide an effective and durable solution for mass transfer applications, especially in systems requiring excellent fouling resistance. Their advanced design, high efficiency, and long-lasting performance make them a preferred choice for improving industrial separation and purification processes. Invest in Plastic Cascade Mini Rings to enhance system efficiency and reliability.

Specifications:

Plastic tower packing can be made from heat resistant and chemical corrosion resistant plastics, including polyethylene (PE), polypropylene (PP), reinforced polypropylene (RPP), polyvinyl chloride (PVC), chlorinated polyvinyl chloride (CPVC), polyvinyiidene fluoride (PVDF) and Polytetrafluoroethylene (PTFE). The temperature in media ranges from 60 Degree C to 280 Degree C

Plastic Tower Packings: plastic pall ring, plastic saddle, plastic super saddle, plastic cascade ring, plastic conjugate ring, plastic teller rosette ring, plastic hi-flow ring, plastic snowflake ring, plastic VSP ring, plastic tri-pack, etc.

Physical & chemical properties of plastic Random Packing:

| Performance / Material | PE | PP | RPP | PVC | CPVC | PVDF |

| Density (g/cm3) | 0.94-0.96 | 0.89-0.91 | 0.93-0.94 | 1.32-1.44 | 1.50-1.54 | 1.75-1.78 |

| Operation Temp.(oC) | 90 | >100 | >120 | >60 | >90 | >150 |

| Chemical corrosion resistance | Good | Good | Good | Good | Good | Good |

| Compression Strength(Mpa) | >6.0 | >6.5 | >7.0 | >6.0 | >8.0 | >10.0 |

● Lifespan: more than 3 years.

● Package: plastic bags, cartons.

Table 1: The Technical Parameter of Plastic Cascade Mini Ring | ||||||

Item | Size | Surface Area | Voidage | Bulk Number | Bulk Density | Dry Packing Factor |

PCMT-01 | 16 × 8.9 × 1 | 370 | 85% | 299136 | 135.6 | 602.6 |

PCMT-02 | 25 × 12.5 × 1.2 | 228 | 90% | 81500 | 65 | 312.8 |

PCMT-03 | 38 × 19 × 1.2 | 132.5 | 91% | 27200 | 54 | 175.8 |

PCMT-04 | 50 × 25 × 1.5 | 114.2 | 92.7% | 10740 | 43 | 143.1 |

PCMT-05 | 76 × 37 × 2.6 | 90 | 92.9% | 3420 | 44 | 112.3 |

Features:

·Large capacity.

·Fouling resistance.

·Low pressure drop.

·High mechanical strength.

·Strong corrosion resistance.

Applications:

·Suitable for methanol and organic acids separation.

·Applied in desulfurization and decarbonization system.

·Applied in absorption, extraction, scrubbing, stripping and heat transfer.

·Used in gas dehydration, methane and carbon dioxide removal, etc.

·Applied in carbon dioxide degassing towers, ozone exposure reaction towers, vacuum distillation towers and other reaction towers.

<< Previous page

Next page >>