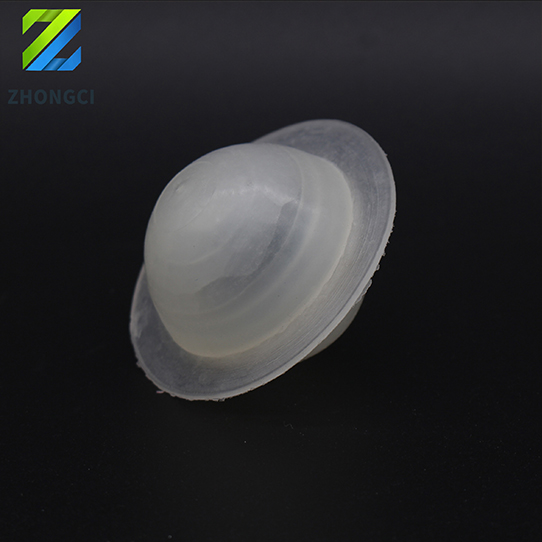

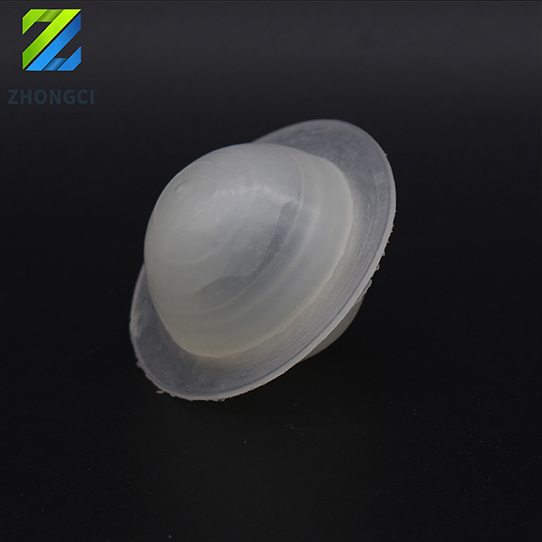

Plastic Liquid Surface Covering Ball

Plastic liquid surface cavring ball has two kinds of models: one is liquid surface covering ball with edge and the other is without edge . The liquid surface covering ball with edge has the characteristics of stable gravity center, overlapping edge and edge, and good covering effect. Its function is to inhibit the volatilization of acid mist.

Quick Details

A Plastic Liquid Surface Covering Ball is a floating ball designed to cover the surface of liquid storage tanks, ponds, and treatment basins. It helps reduce evaporation, control heat loss, and prevent contamination from dust and debris.

Reduces Evaporation Loss – Minimizes water or chemical loss in storage systems.

Controls Heat Retention – Helps maintain temperature stability in tanks and basins.

Prevents Contamination – Reduces dust, debris, and algae formation on liquid surfaces.

Lightweight and Durable – Provides long-lasting performance with minimal maintenance.

Chemical and UV Resistance – Withstands harsh environmental and chemical conditions.

Prevents evaporation and heat loss in treatment plants and reservoirs.

Reduces chemical loss and maintains purity in liquid storage systems.

Improves efficiency by reducing heat loss and unwanted vapor emissions.

Protects against contamination and minimizes water loss due to evaporation.

Highly Effective in Reducing Evaporation – Helps conserve valuable liquids.

Enhances Energy Efficiency – Reduces the need for additional temperature control measures.

Prevents Algae Growth – Limits sunlight exposure to reduce biological growth.

Low Maintenance and Easy Installation – Simply place the balls on the liquid surface for immediate benefits.

Determine the Required Quantity – Cover at least 90% of the surface for optimal performance.

Evenly Distribute Across the Liquid Surface – Ensure uniform coverage to maximize effectiveness.

Monitor and Maintain as Needed – Periodic checks ensure continued efficiency.

Plastic Liquid Surface Covering Balls provide a simple yet highly effective solution for evaporation control, heat retention, and contamination prevention in various industries. Their durability, chemical resistance, and easy application make them an ideal choice for liquid storage and treatment systems. Invest in Plastic Liquid Surface Covering Balls to improve operational efficiency and protect valuable resources.

Material: PP

Physical & chemical properties of plastic tower packing:

Technical Date

Item | Size (mm) | Density (g/m³) | Application Temerature °C | Crushing Strength Mpa | Packing Number pieces/m²

| Void Rate % | Covering Rate % | PH |

Covering Ball No Border | 40 | 0.5 | ≤120 | ≤0.4 | 720 | 95 | 91 | 1-1.4 |

Covering Ball No Border | 50 | 0.5 | ≤120 | ≤0.4 | 500 | 95 | 91 | 1-1.4 |

Covering Ball With Border | 40 | 0.3 | ≤120 | ≤0.4 | 666 | 93 | 97 | 1-1.4 |

Covering Ball With Border | 80 | 0.5 | ≤120 | ≤0.36 | 232 | 95 | 99 | 1-1.4 |

Liquid Surface Covering Ball | 40 | 0.3 | ≤120 | ≤0.4 | 666 | 93 | 97 | 1-1.4 |

Liquid Surface Covering Ball | 80 | 0.5 | ≤120 | ≤0.36 | 232 | 95 | 99 | 1-1.4 |

Application:

It is mainly used to cover the upper layer of liquid surface. For example, it can prevent the spillage and volatilization of the acid and alkali gas, reduce the pollution of the external environment of the acid and base gas, and have the effect of saving acid and alkali materials. It can separate air and water ,then can reduce the pollution of desalted water by CO2,O2 and dust impurities in the air, and ensure the quality of water.

Usage: Add the covering ball to the liquid according to the number of surface area, the covering ball is arranged naturally and covered on the liquid surface, the edge can be sealed by other sealing material.

<< Previous page

Next page >>